The aluminum water refining can reduce the gas and certain impurities, and meet certain properties.

Aluminum water refining has two stages: furnace refining and online refining. The former is preliminary and relatively rough refining. The latter is carried out during the flow of molten aluminum from the furnace to casting machine.

Flux refining mainly involves the interaction between the flux and the melt. The reduced viscosity of the melt makes the oxidized inclusions easy to precipitate and float. Some components in the flux can react with aluminum, and the generated gas can also play a role in degassing.

The powder spraying refining device uses nitrogen to evenly spray the powder flux into the melt. Add powdered flux to the material box. When the motor drives the screw to rotate, the flux powder is pushed into the mixing chamber, and then the flux is mixed with nitrogen and brought into the melt along with the nitrogen flow.

In order to improve the refining effect, we must pay attention to the quality of flux and carrier gas. The flux is usually susceptible to moisture, so the powder flux should be placed in a dry place and sealed for storage. Nitrogen should be of high purity (purity is preferably 99.99%). The lower the oxygen and water content, the more significant the degassing effect.

In addition to flux refining, on-line degassing filtration is the key research and development target of aluminum enterprises melting and casting production.

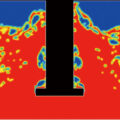

Aluminum foundry adopts flux refining and online degassing filtration system. The online degassing system adopts dual-rotor degassing

refining technology. The dual-rotor gas refining device has high efficiency in removing gases and inclusions in the aluminum melt. It can achieve a satisfactory hydrogen removal effect and ensure the inside of the ingot quality. The gas passes through the nozzle to form dispersed fine bubbles. At the same time, the melt is stirred with the rotation to make the bubbles evenly dispersed in the entire melt, so as to achieve degassing and slag removal effect.