It is needed the Aluminum Melt Refining in the lone smelting process. Because the aluminum Melt is easy to oxidize, inhale, and absorb metal impurities. Therefore, it is very easy to be polluted during the smelting process. Preventing the contamination of impurities is an important issue in the smelting of aluminum and aluminum alloys. The […]

Ceramic Disc Filter can remove the small and suspended non-metallic inclusions in the aluminum melt. It is a variety of new methods for purifying aluminum melt have been developed at home and abroad. With the development of science and technology, the requirements for alloy materials are getting higher and higher, especially in the use of […]

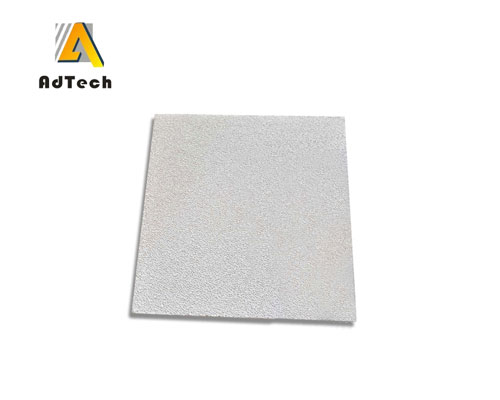

Ceramic Foam Filter Suppliers have developed foam ceramics as a new type of ceramic filter material for many years. Generally, a filter plate with a thickness of 50mm and a length of 200~600mm is made, and the porosity is 0.8-0.9. When the foam ceramic filter is filtering the aluminum liquid, the aluminum liquid flows through […]

Because the degassing and refining methods can not clean all the oxide inclusions in the melt, and often bring adverse effects on the quality of aluminum processing materials, the method of Metal Foam Filters filtering and slag removal was adopted in modern times, and the aluminum liquid becomes pure. The main functions of mechanical slag […]

In order to obtain the best mold fill rate, it is important to calculate the appropriate ceramic foam filter size for each specific casting application. The ceramic foam filter must be large enough so that it does not obstruct or block the flow of molten metal or be blocked by residual inclusions until casting is […]

The existence of non-metallic inclusions is not conducive to the production of high-quality castings. The high mechanical properties that can be obtained are the key aspects that are easy to lose in the presence of inclusions and scale. The mechanical properties of high strength aluminum alloy are very sensitive to the notch or defect in […]

In recent years, Foam Furnace Filters have been developed as a new type of molten metal filter to reduce casting defects. It plays an important role in the metal casting and casting industry, in which they are used to remove impurities in molten metal to improve the quality and performance. Final product. Even the smallest […]

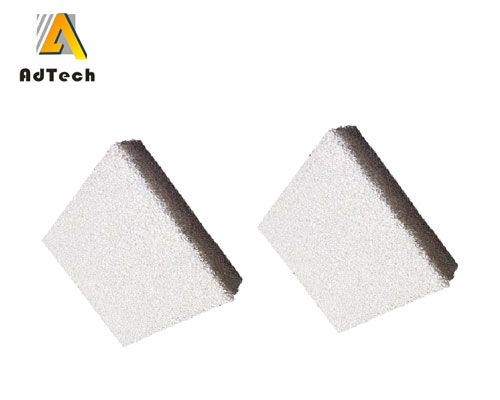

Honeycomb Ceramic Filters are a special technology. They have the porous structure of foamed ceramic products, and has the characteristics of lightweight, chemical stability, large through-hole rate, high corrosion resistance, high strength, and good thermal shock resistance. Working Principle of Honeycomb Ceramic Filters Ceramic foam filters are characterized by high temperature resistance, corrosion resistance, corrosion […]

Ceramic foam filter plate is a new type of filter plate, which is made of Open Cell Foam Filter Materials. When the ceramic foam filter plate filters aluminum liquid, the aluminum liquid flows through the tortuous holes of the ceramic filter plate. The nonmetallic impurities and oxide film (commonly known as slag) in the liquid […]

Aluminum Alloy Melting and Refining Metal Melt (1) Solid liquid ratio: according to the charging amount required by the product specification, the solid material with solid-liquid ratio of 40% and electrolytic aluminum liquid of 60% is specified. (2) Charging sequence: when the furnace temperature reaches above 800 ℃, the charging shall be started. First, the […]