The surface of the aluminum material has an uneven thickness of the oxide film, sometimes also absorbs water, is mixed with sand, sticky with oil stains, and painted with paint. When melting, the aluminum material is further oxidized in a high-temperature environment, the thickness of the oxide film increases, and it reacts with moisture to produce aluminum oxide and hydrogen, which increases the oxidation inclusions and gas content. Therefore, after the aluminum material is melted, it must be purified to remove impurities and gases inside the aluminum liquid. Flux for Aluminum Melt Purification is used to purity in the furnace.

Flux for Aluminum Melt Purification

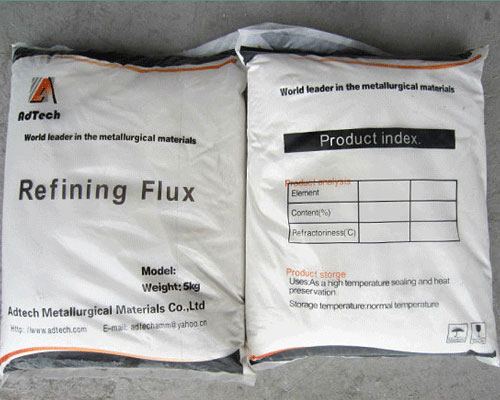

The substances used to purify aluminum liquid are collectively called flux. The flux is mostly solid or gas at room temperature, and some fluxes are liquid. The granulated flux has the advantages of small volume, easy transportation and storage, but all have strong hygroscopicity and must be sealed and packaged. In order to improve the purification effect of the solid flux, the flux can be compressed into tight small pieces and wrapped in an aluminum box, placed in a long-handled drilling container and inserted into the bottom of the molten pool.

The flux should be stored in a dry place with high room temperature before use, such as next to the furnace, to prevent moisture. Applying the covering flux in the furnace can reduce the melting consumption and prevent the aluminum liquid from absorbing gas from the furnace atmosphere, but the consumption of the covering flux is large (about 10% of the weight of the aluminum material), which increases the production cost. Small and medium-sized aluminum Processing plants are generally not used. The purification flux is usually used to scatter the powdered flux mixed in the proportion after the aluminum material is melted, and then stir the aluminum liquid with a long-handled tool to promote the slag to float. During the agitation process, part of the flux is added into the molten pool, and chemically reacts with the aluminum liquid to form a gaseous substance insoluble in aluminum, which plays the role of degassing and ash removal during the rise of bubbles.