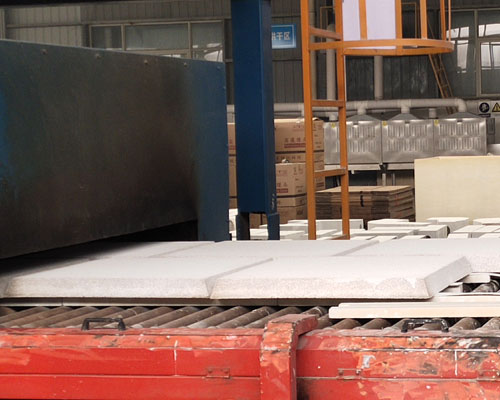

The CFF filtration system uses a dedicated ceramic foam filter to remove the inclusions generated between the refining system and the mold table. Contamination of molten metal by hard metals, leading to casting finishing problems, is the main reason for the introduction of filter systems in aluminum foundries. Eliminate bad defects, such as casting fastness, porosity, […]

Flux for aluminum smelter is an important auxiliary material used in aluminum alloy smelting. The main components of current fluxes on the market are chloride and fluoride. Among them, chloride has strong water absorption and is easily damp. Therefore, the raw materials used in flux production must be dried. Completely remove moisture, seal the package […]

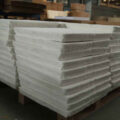

The square ceramic foam filter is widely used in molten aluminum filtration in the aluminum casting process. It can prevent particle impurities in molten aluminum from entering the slab and improve the quality of aluminum processed products. The square ceramic foam filter plate is generally installed in the filter box, which can effectively filter out […]

The rotating degassing equipment for aluminum alloy refining can remove hydrogen and slag, purify aluminum liquid, and eliminate pinholes in castings. The online rotating degassing device adopts the refining process of rotating degassing and has a long service life. The degassing rotor, heater protection sleeve, and thermocouple protection sleeve are all made of ceramic manufacturing […]

The refined flux is white (gray) fine powder, and its main components are compounds such as chloride and magnesia. After heat treatment and screening treatment, the product has a uniform particle size and is widely used for refining cast aluminum alloy in reverberatory furnaces and holding furnaces. Adding aluminum refining agent to aluminum smelters can […]

Ceramic foam filter for metal filtration has been used for many years, it can improve the quality of castings and obtain high-quality aluminum die castings. The main function of the filter is to enable many users to remove foreign matter from molten metal. In Europe, most ceramic foam filters are used to reduce inclusions in […]

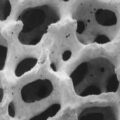

The ceramic foam filter for aluminum casting has high chemical stability. The main component of the ceramic foam filter is Al2O3, which will not react with aluminum at high temperatures. The ceramic foam filter should have sufficient strength. Alumina ceramic foam filter is relatively brittle and hard. When the strength is insufficient, it is easy […]

Ceramic foam filter molten metal filtration is closely related to obtaining a satisfactory filtering effect of molten aluminum. Ceramic foam filters can improve the cleanliness of aluminum melt. The alumina ceramic foam filter can effectively eliminate large impurities and small impurities of several microns in molten aluminum. You can choose a suitable filter plate according […]

The alumina foam ceramic filters can effectively remove micron-sized impurities in the aluminum melt, making the aluminum water a stable laminar flow, which is good for filling. The ceramic foam filter has good mechanical strength and chemical stability, and excellent aluminum corrosion resistance. Strictly control the pore size and through-hole rate to obtain a stable […]

The molten aluminum degasser can achieve the purpose of purifying aluminum alloy. The degassing device can meet the high technical performance requirements of producing aluminum alloy. The aluminum degasser is located between the furnace and the casting machine. Its main function is to remove hydrogen and other residues. It can reduce the porosity of castings. […]