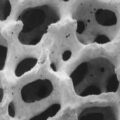

The CFF filtration system uses a dedicated ceramic foam filter to remove the inclusions generated between the refining system and the mold table.

Contamination of molten metal by hard metals, leading to casting finishing problems, is the main reason for the introduction of filter systems in aluminum foundries. Eliminate bad defects, such as casting fastness, porosity, low uniformity, etc. The ability of the ceramic foam filter to capture these inclusions is critical to keeping the ingot clean during the metal solidification process. Therefore, the quality and productivity of downstream operations (such as forging, extrusion and rolling) are guaranteed.

The CFF filtration system is suitable for the filtration of molten aluminum under a long-term temperature load. The size of the ceramic foam filter depends on its porosity, AdTech can provide 10 to 60 PPI. Customers can choose according to filter capacity, casting time and filter box layout. In the continuous or discontinuous movement of the metal casting process (ranging from a few tons to hundreds of tons), a large-area filter should be used for filtration.

The choice of filter porosity depends on the specific alloy, casting temperature, metal contamination and required output quality. Before casting, the filter must be fully preheated to ensure its normal operation.

AdTech’s precision-designed filter unit is unique. Their development and design are based on our own metallurgical engineers’ years of experience in the field of aluminum melt filtration and melt transfer technology. The filter system uses a new type of high-silicon melting manufacturing technology. The filter box can also be customized according to the customer’s metal filtration requirements.

The aluminum liquid filtration system is the most effective method, which can reduce the manufacturing waste rate of the final product and improve its quality. The manufacture of aluminum alloy meets the requirements for higher purity cast metal to improve the quality of the final product (foil, block, ingot, rod, profile).