Ceramic foam aluminium filter is an open-cell mesh with a sponge-like structure for filtering aluminum melt. It is widely used by aluminum foundries. The ceramic foam filter is a filtering device that uses ceramic foam as the filter medium. The ceramic foam filter has the advantages of high filtration precision, low cost, simple device, convenient operation, and maintenance, etc.

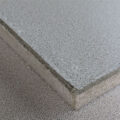

The ceramic foam aluminium filter is installed in the filter box of the molten metal transfer system between the static furnace and the casting table. The filter bowl is welded with an ordinary steel plate, lined with insulation felt, and the innermost layer is refractory bricks. The depth of the filter bowl is generally not less than 200mm. The molten aluminum flows from the static furnace to the crystallizer after being filtered through the filter bowl. The filtering effect of ceramic foam depends on the thickness, pore size and shape of the ceramic filter, and the speed at which the melt approaches the filter.

The pore characteristics of the foam ceramics currently put into practical use are as follows: the number of pores is 10-45 pores/in (1in-25. 4mm); the porosity is 85% 90%; the bulk density is 0.35-0. 40g/cm3; Specific surface area, 10000in2/in3; the thickness of the ceramic plate, 20″100mm.

The flow characteristics of ceramic foam depend on the pore characteristics and the size of the ceramic plate. For a foam ceramic board with a size of 305mm 305mmx51mm and a number of holes of 30 holes/in, the filtration capacity is about 1.7-3.0 kg/s.

When filtering aluminum melt, the main filtration parameters of ceramic foam aluminium filter are: filtration precision 2um, filtration efficiency 99%, the initial pressure head is 50-150mm, and effective working pressure head is 50mm.

The ceramic foam filter has the advantages of high filtration accuracy, high filtration efficiency, light weight, small footprint, convenient operation and use, and good working conditions. However, the foam ceramics are discarded once used and cannot be regenerated, and the texture is relatively brittle, so the mixing of fragments should be avoided during installation.