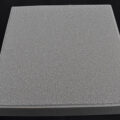

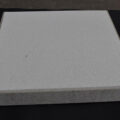

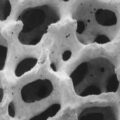

CFF ceramic foam filter plates are popular because of their low cost, compact structure, simple operation, and better filtering effect.

Compared with the corundum tube, the CFF ceramic foam filter has a larger pore diameter, a smaller density, and a lower filtration accuracy. Compared with the deep-bed filter, the filter layer is thin, and there are less impurities and particles that can be adsorbed. But this can be improved by increasing the number of filtration stages, that is, two-stage and three-stage filtration can be used to improve filtration accuracy. Its advantages are small initial pressure head, convenient replacement, simple operation and better filtering effect.

The advantages of the deep bed filter are thick filter layer, long flow path, and many impurity particles adsorbed. Large over-flow, suitable for large-scale and mass production. However, deep bed filtration only uses filling to form a filter layer, and the filter medium is easy to loosen and move, causing some small impurities to be stirred into the melt and reduce the filtering effect.

The filter tube of the tubular filter adopts a fixed structure, the structure of the filter tube itself does not loosen and move like the filter layer of the deep bed, so the filtering effect is good. However, the initial pressure head of the filtration is large, the replacement of the filter tube is more troublesome, and the filtration cost is higher.

In order to improve the filtration accuracy, the pore size of the ceramic foam filter plate has been developed from 20-50 PPI to 60 PPI, 70 PPI, and a composite filter plate appears, that is, the filter plate is divided into upper and lower layers, with a large pore size on the top and small pore size on the bottom. 30/50 PPI, 30/60 PPI, 30/70 PPI. The composite filter plate has a good filtering effect and a large amount of metal passes through.

In semi-continuous casting, the original casting process stipulates that the filter plate must be replaced every time the casting, that is, the filter plate is only used once. In other words, it can be thrown away without seriously affecting the filtration efficiency.

The metal flow rate of the filter affects the filtration efficiency: the flow rate is set correctly, and the filter after continuous use is very efficient. When the speed is too fast, the efficiency continues to decline over time.