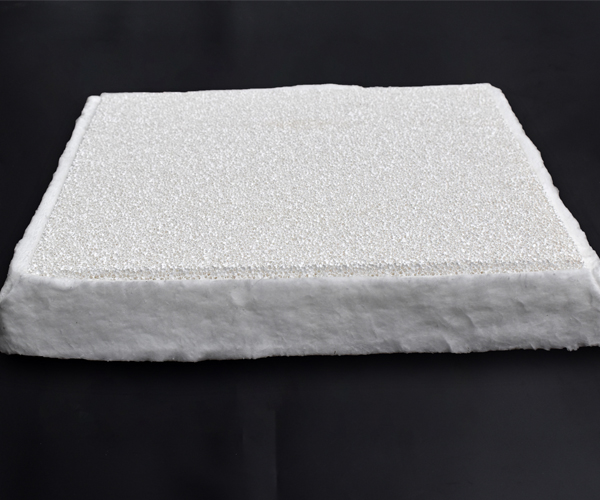

Ceramic foam filter (CFF) is currently the most widely used filter for aluminum melt filtration. Its advantages are high porosity, high filtration efficiency, convenient replacement, low cost, strong adaptability, and can filter solid inclusions and separate some liquid inclusions.

Due to the oxygen affinity of aluminum, oxides are the most common among all aluminum alloy melt inclusions. The oxides in the aluminum melt have different types and shapes, which depend on the time, temperature and thickness of the oxidation. Oxides will appear during pretreatment, smelting, refining, pouring and heat treatment. As long as the aluminum melt is in contact with oxygen, oxide inclusions will be formed.

In the process of smelting and refining aluminum alloy, it is often necessary to add fluxes for protection, slagging, degassing and impurity removal, and refinement. The flux will bring in some impurities.

Whether the inclusion particles can be removed is related to the collision probability, and also depends on the adsorption capacity of the surface of the ceramic foam filter plate in contact with the melt. The stronger the affinity of the material forming the filter plate with the inclusion particles, the more microscopic defects on the surface of the hole. The more helpful the adsorption and retention of inclusion particles.

Ceramic foam filter is mainly used for aluminum melt filtration in foundries. Because the filter has excellent resistance to erosion and corrosion by molten aluminum, it can effectively remove inclusions, reduce residual gas, and provide laminar flow. Therefore, the filtered metal can improve the quality of castings, reduce waste, and reduce inclusion defects, all of which help to increase profits.

At present, it is more customary to use PPI (holes per inch) to express the size of the pore size of the filter plate. After the molten aluminum is passed through a 10ppi foam ceramic filter plate, there are no impurities above 6um in the filtered A356 scrap aluminum alloy, and the tensile strength and elongation are increased by 19.2% and 116.7%, respectively. This is because impurities below 10 pm tend to accumulate on the filter plate, thereby improving the filtration efficiency.