The selection of the ceramic foam filter plate should be based on the quality of the impurities in the aluminum melt, the flow rate of the melt transfer and the quality requirements of the cast aluminum products.

Aluminum melt contains a lot of impurities, and the quality requirements of cast products are general. You can choose a foam ceramic filter plate with a larger mesh, and add a glass cloth before the filter plate for coarse filtration.

In the semi-continuous casting of aluminum melt, it is important to filter it with glass cloth first. It can intercept the slag flowing out when the furnace eye is opened and the slag washed down on the launder to prevent the filter plate from being blocked.

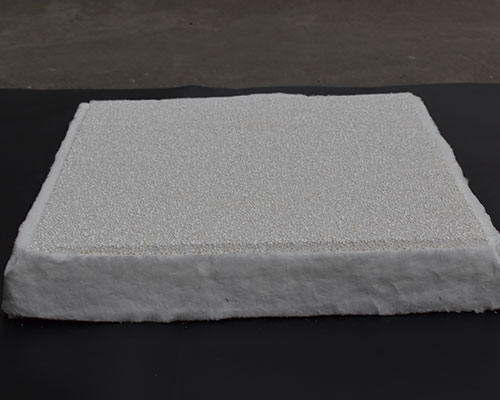

When the quality requirements of cast products are high, small meshes (large mesh foam ceramic filter plates) are used, such as the production of aluminum foil blanks, high-quality hot-rolled slabs, high-quality military aluminum, and high-quality industrial aluminum profiles. At the same time, AdTech foam ceramic filter plates can be used. If you choose 30ppi and 60ppi ceramic plates with specifications of 305 mm × 305 mm × 50 mm, 381 mm × 381 mm × 50 mm, 432 mm × 432 mm × 50 mm, 508 mm × 508 mn × 50 mm for dual-stage filtration, aluminum melt can achieve the desired cleanliness.

The selection of the filter plate size is determined by the flow rate of the aluminum melt per unit time and the total throughput of the aluminum melt. If the flow rate is large, the total throughput is large, and the filter plate has small holes, a larger size filter plate should be used. AdTech Ceramic Foam Filters are available in all common sizes: 7″, 9″, 12″, 15″, 17″, 20″, and 23″. We offer the whole range of porosities from PPI 10 up to PPI 60 (PPI = pores per inch). Custom-made cut-to-size filters are also possible.

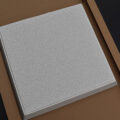

Advantages for AdTech Ceramic Foam Filter Plate

Adopt adsorption principle for Ceramic Foam Filter, can effectively remove big piece inclusions in molten aluminum, and effectively adsorb tiny inclusions.

No broken bits drop out, effectively reduce the pollution of molten aluminum.

Superior thermal shock resistance, improve erosion resistance ability of molten metal.

Automatic flow production,3 calibration procedures,precision size,fit the filter housing tightly.

Improve the surface appearance and performance, purify molten aluminum.