In the 1980s, ceramic foam metal filtration technology was quickly and widely adopted in the market and was used for a wide range of high quality aluminum products, including rigid packaging materials, lithographic printing molds, aerospace products such as wafers, wafers, forgings and extrusions; bright decorations Decorative surface decorations, condenser tubes, foil, building profiles, cast alloys and electrical conductors, cables and wires.

The ensuing rapid market acceptance and technological development in the aluminum field. The different types and complexity of foundries are due to the following reasons: ease of use and acceptability of the operator; operational flexibility; low operating and installation costs; effective removal of inclusions; Small footprint requirements.

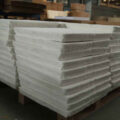

Before molten aluminum is solidified into an ingot or billet by filtration, it is best to remove the inclusions in the final processing step. Ceramic Foam Metal Filtration technologies have been used in aluminum foundries over the years.

The modern process of purification of molten aluminum, the filter is close to the completion of the last cleaning process of the casting.

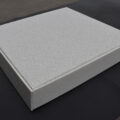

Prior to this, after flux refining in the furnace, standing, medium and adsorption without medium, although 60% to 80% of inclusions and gas have already been removed, but the melt was still dispersed with finer (grain diameter usually <15 μm) (including inclusions of secondary raw material in the chute and intermediate production contract).

To obtain high quality aluminum products, we must ensure that these small inclusions are collected and separated by adsorption.

Compared to other purification methods, the filtration method has become the preferred method for the final purification of molten aluminum due to its low energy consumption, ease of operation, high purification efficiency, and less secondary pollution.

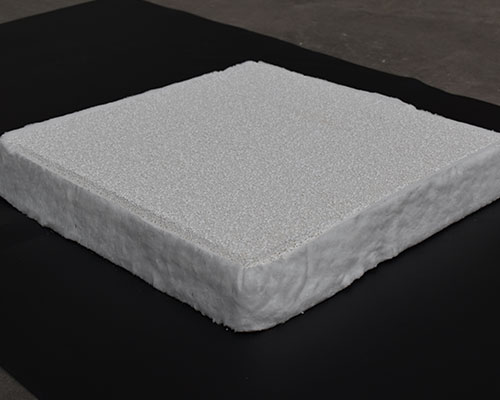

The aluminum ceramic foam filter is the most widely used filter in the field of filtration of molten aluminum. The advantage is high porosity, high filtration efficiency, ease of replacement, low cost, manufacturability; a part of liquid inclusions can also be separated by filtration of solid inclusions.