Foam Ceramic Filter for Molten Metal Filtration has been used in semi-continuous casting and molded castings in the United States, Japan, Canada, Switzerland and other countries, and has also been widely adopted in my country.

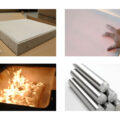

In the process of aluminum melting and casting, bubbles, oxide film and non-metallic inclusions destroy the continuity of metal materials, reduce the effective load-bearing section of the casting, and cause stress concentration, which reduces the mechanical properties of the casting and deteriorates the processing performance.

In order to avoid these hazards, in addition to cleaning the charge, it is also necessary to purify the aluminum melt. According to their different mechanisms and forms, they can be divided into the following three categories:

(1) Adsorption purification: During the smelting process, chlorine, nitrogen or inert gas is passed into the aluminum liquid, or some chloride salt (such as ZnCl2, MnCl2, CCL4, etc.) that can react with the aluminum liquid to form bubbles is added, which is the so-called bubble Up float. Or use KC1 and NaCI to make a flux, relying on the adsorption of the refining agent to achieve the purpose of removing the gas and inclusions in the alloy.

(2) Physical purification: Purify the aluminum melt with the help of physical processes, such as ultrasonic treatment, direct current treatment and vacuum treatment.

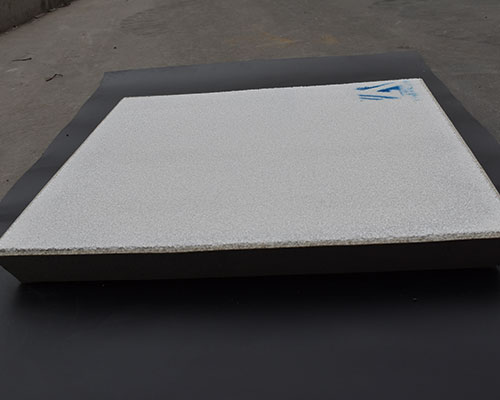

(3) Filtration and purification: the molten metal flows through ceramic foam filter medium, and the inclusions are captured, thereby purifying the metal.

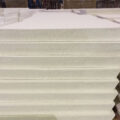

The emergence of ceramic foam filter provides a high-efficiency filter for the production of cast aluminum parts. Many countries in the world have generally used it for the production of semi-continuous ingots and shaped castings.

The technology of AdTech foam ceramic filter for molten metal filtration has been widely approved by the market, applied for producing multiple series of aluminum alloys products, such as PS baseboard for printing, canning materials, flexible packaging materials, railway vehicle, aerospace products, cables, electrical wires and other high-precision filtration and purification for casting aluminum alloy.