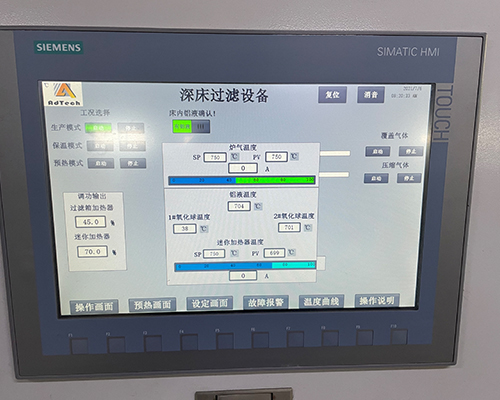

The deep-bed filters, also known as the particle accumulation filters, are mainly composed of layered strengthened alumina balls stacked according to a certain particle size ratio. The deep bed filter can filter inclusions above 10um, with high filtration efficiency, large filtration capacity, long service life and good regeneration. However, it has a long preheating time and high replacement cost, which is suitable for melt filtration with high performance requirements and a large processing capacity.

The chemical composition of the non-metallic inclusions formed in the aluminum melt is very stable, and it is easy to cause cracks in the castings after solidification. The presence of non-metallic inclusions will reduce the fluidity of the metal and reduce the mechanical properties of the casting. Due to the high hardness of non-metallic inclusions, the cutting performance of castings will be reduced. Non-metallic inclusions are also related to the formation of holes in castings. Non-metallic inclusions have poor wettability with aluminum melt, and their microscopically rough surface can easily serve as nuclei for pores or shrinkage cavities. The hydrogen in aluminum is easy to deposit on non-metallic inclusions, and form pores after cooling.

Removal of non-metallic impurities can also be achieved by filtration. Filtration can be divided into two stages: the migration of inclusions to the filter medium and the adhesion on the surface of the filter medium. The filtration efficiency mainly depends on the flow state of the molten metal in the filter, the physical and chemical properties of the melt, inclusions, and the geometric parameters of the filter. The filtration of inclusions larger than 30um mainly relies on mechanical blocking, while the filtration of inclusions smaller than 30um is generally considered to have two basic mechanisms: depth filtration and filter cake filtration.

The deep bed filters filter the aluminum alloy melt, and the elongation of the aluminum melt is increased by 17.93% after filtering, and there are only a few 6um impurities, while the unfiltered aluminum alloy has many 40um impurities. This is because the aluminum melt enters the filter through its own gravity. This process increases the contact between the inclusions and the filter particles, and the impurities are easily captured by the active particles, thereby improving the efficiency of impurity removal.