In the production process of cans, aluminum alloys need to be processed by hot rolling, cold rolling, and deep drawing, which requires high melt quality and ingot quality. In production, more advanced filters are usually used for melt purification. The deep bed filter for foundry is one of the commonly used filters.

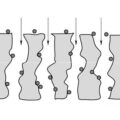

The deep bed filter for foundry is made up of multiple layers of alumina balls and a layer of alumina gravel of appropriate size stacked in a unique way, and the thickness of the filter medium reaches 500 mm. The size and stacking method of alumina balls and gravel should be adjusted according to different alloys. Inclusions are adsorbed on the surface of the medium in four ways: direct interception, Brownian motion, inertial force, and gravitational precipitation.

The deep filtration technology has been recognized in the casting field and can meet the needs of high-end products with higher quality requirements. The deep bed filter has the advantages of large filtration area and high filtration efficiency. For impurities greater than 5um, the filtration efficiency is greater than 90%.

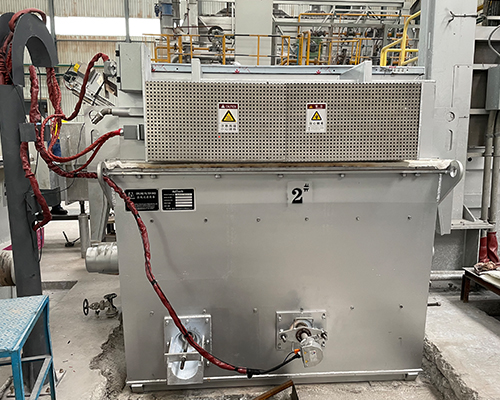

How to use deep bed filters efficiently directly affects product quality, production efficiency, and cost. The wettability of aluminum melt to alumina is closely related to the melt purification process.

The pore size of the filter layer of the deep bed filter is 100 times larger than the size of the impurity particles to be filtered. If the filtration speed is 0.1~0.4cm/s. The interception and adhesion of impurity particles by the filter layer are maximized. Contrary to the ceramic foam filtration method. The deep-bed filter is not affected by changes in the density of impurity particles.

In production practice, it is required that the liquid metal must completely fill the entire space of the filter layer, otherwise, the filter efficiency of the filter will be reduced, and the service life of the filter bed will also be affected. During use, the upper and lower heating devices are used to heat and keep the filter, which can keep the filter long service life, and the cast metal can reach more than 7000t. Therefore, the deep bed filter for foundry is suitable for the production of larger batches of alloys.