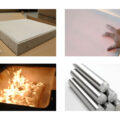

After the aluminum melt is refined in the smelting furnace, refining in the static furnace, and online refining, the gas content has been greatly reduced, and it is basically in a critical minimum state. Larger particles of inclusions in the melt are basically carried by the refining agent, but there are still a certain number of small particle inclusions in the melt, which will have a certain impact on the mechanical properties and physical and chemical properties of the material. Therefore, the molten metal needs aluminum filters for filtration before casting.

At present, ceramic foam filters are the most economical aluminum filters. The foam ceramic filter molten metal aluminum filtration can be used with tube filters or deep bed filter equipment. Ceramic foam filters can extend the service life of this expensive equipment and reduce the cost of aluminum foundries.

After the melt passes through the smelting furnace, static furnace, and online refining, the particle size of its inclusions no longer changes. Once the filter is selected, its porosity is a fixed number. The filtration efficiency is related to the thickness of the filter and the speed at which the melt passes through the filter. The greater the thickness of the filter, the better the filtering effect. The faster the melt passes through the filter, the worse the filtering effect. Cast-rolling production has a small amount of melt filtration per unit time, slow flow rate, and casting-rolling is mostly pure aluminum and soft alloys. There are few inclusion particles, the inclusions are easily absorbed by the filter, the filtration efficiency is high, and the melt is relatively easy to purify. Generally, 50PPI and 30PPI ceramic foam filters are used for filtration.

Using the right high-temperature Materials will affect your productivity in a positive way! AdTech specially designed Ceramic Foam Filters are made of the basic raw material Aluminium Oxide. They are manufactured with porosities varying from 10 to 60 pores per inch (PPI). Also, combo sets are made in 20-30 PPI and other selections are possible. Different sizes and custom-made filters are manufactured according to specifications.