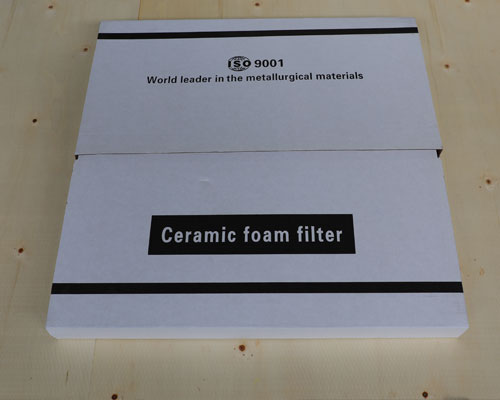

The molten metal filtration of ceramic foam filters (CFFs) has been used for commercial purposes in the foundry industry, and has been used in the aerospace industry to produce high-quality aluminum castings for such products for more than 40 years. In recent years, more and more CFFs have been used in the non-ferrous and non-ferrous metal industries. The non-ferrous metal industry, which is very important in the physical purification of metals, is the most commonly used filter medium, especially in the aluminum casting industry.

It is well known that molten metal filters for foundry can remove foreign and natural impurities in the melt based on its structural characteristics, and has low flow resistance and high filtration efficiency exceeding 10-20 microns.

The structure of molten metal filter creates a unique tortuous path for fluid flow, which traps inclusions and allows clean, smooth flowing metal to enter the cavity. CFF is generally considered the best conversion filter. Their main advantages are: high filtration efficiency, reduced turbulence, refractoriness and corrosion resistance, suitable for the most demanding casting applications.

For ceramic foam, its good heat resistance and high porosity characteristics make it useful as a filter for purifying molten metal. Ceramic foam is also used in catalytic combustion, burner intensifiers, soot filters for diesel exhaust, catalyst carriers and biomedical equipment.

Molten Metal Filters for Foundry

- Ceramic foam has high mechanical strength, chemical stability, high thermal shock resistance and resistance to liquid metal flow impact even in high temperature environments.

- Reduce the gas and inclusions in the casting and reduce the turbulence of molten metal when filling the mold.

- Reduce the surface defects of castings and significantly reduce the rejection rate of castings.

- Increase the compression and sealing of the casting, increase the elongation and tensile strength of the casting, improve the surface finish of the casting, increase the fluidity of the molten metal, and increase the filling capacity and feeding capacity of the melt.

- In order to ensure the quality of molten metal and stable chemical composition, there is no slag or breakage during processing.

- In the case of large and stable metal flow, even if the molten metal contains high inclusions, it will not block the ceramic foam filter.

- It has high dimensional accuracy and can be automatically placed on the production line.