Aluminum is one of the most used materials in casting practice. However, iron is one of the most troublesome impurities in aluminum casting materials. During the solidification of aluminum alloys, iron promotes the formation of mesophases, which may impair the performance of the final product. In the secondary aluminum industry, iron pollution may always be caused by a large amount of scrap iron. It is the most effective method to remove iron from molten aluminum through a ceramic foam filter (CFF).

Ceramic foam filters (CFFs) have been used commercially in the aluminum foundry industry for more than four decades. CFFs are industrially applied to remove small solid inclusions (oxides, spinels, or carbides) and large oxide films, primarily for the production of premium quality aluminum products.

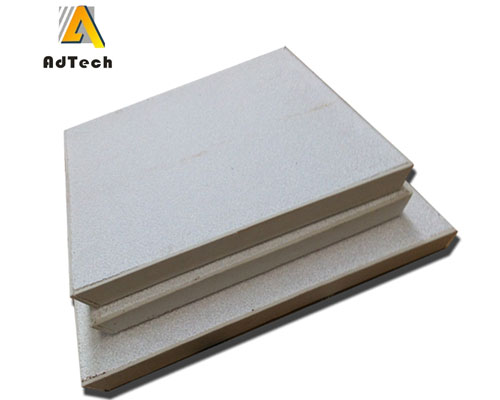

Features of CFF Molten Aluminum Filter

-Uniform pore structure

-High surface strength

-High-temperature resistance up to 1100°C

-Excellent resistance to chemicals used in foundries

Ceramic foam filtration is widely used to enable the removal of non-metallic inclusions from liquid aluminum. Using the right high-temperature materials will affect your productivity. Our ceramic foam filter is made of basic raw material alumina. It is manufactured with pores ranging from 10 to 60 pores per inch (PPI). There are also combination sets of 20-30 PPI and other options are possible. Manufacture different sizes and custom filters according to specifications.

Ceramic Foam Filter Dimension

660x660x50(26″)

584x584x50(23″)

508x508x50(20″)

432x432x50(17″)

381x381x50(15″)

305x305x50(12″)

228x228x50(9″)

178x178x50(7″)

Ceramic Foam Filter Application

1. The casting: 10~25ppi

2. Semi-continuous casting: 30~60ppi

3. High-quality aluminum or sheet: 50~60ppi

4. Continuous casting and rolling: 50~60p

Since the ceramic filter foundry has excellent resistance to molten aluminum corrosion and corrosion, it can effectively remove inclusions, reduce residual gas and provide laminar flow. It is suitable for improving the quality of aluminum alloy and other non-ferrous alloy castings. Improve metallurgical structure and enhance mechanical properties to convert turbulent flow into laminar flow. The molten aluminum filtered through the ceramic foam filter is significantly cleaner. Clean aluminum can produce higher-quality castings in industries such as aerospace, automotive, electronics, and more, all of which help increase profits.