The quality of the alumina foam ceramic filters for foundry in aluminum smelting is very important, which greatly affects the subsequent processing performance and the quality of the final product. Therefore, all countries in the world attach great importance to the purification of aluminum melt.

There are many reasons for aluminum contamination.

On the one hand, during the smelting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-molten state, which is easily oxidized and easily reacts with water vapor. Hydrogen is easy to form various forms of non-metallic slag and coarse intermetallic particles.

On the other hand, part of the waste in the composition charge contains some non-aluminum impurities during the recycling process.

Since the waste comes from process waste, waste from various processes in the factory, and waste outside the factory, the route is different, the composition is complicated, and the quality is poor.

These impurities are easy to cause bubbles and inclusions in the slab, thereby seriously affecting the purity of the metal melt, thereby further affecting the processing performance, mechanical properties, corrosion resistance, and appearance quality of the product.

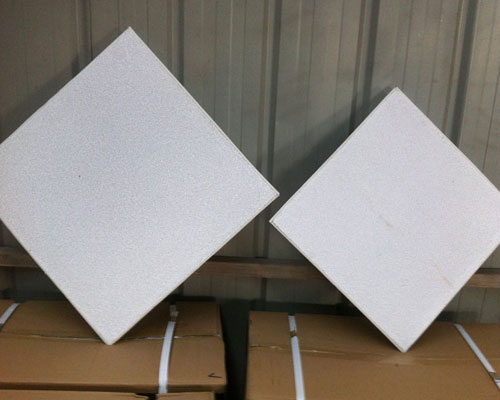

The ceramic foam filter for casting is mainly used for filtering aluminum and aluminum alloy in foundries. It has excellent corrosion resistance and aluminum melt corrosion performance, can effectively remove inclusions, reduce residual gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metals can produce higher-quality castings, reduce scrap and reduce inclusions, all of which help increase profits.

The alumina foam ceramic filters for foundry can effectively remove various fineness of micron inclusions in the molten aluminum, so that the molten aluminum becomes a smooth laminar flow, which is good for filling. It has a unique corundum structure, good mechanical strength and chemical stability, excellent aluminum cleaning; strictly control the size of the pores and the ratio of through holes to achieve stable filtration.

The ceramic foam filter is surrounded by a sealed ceramic fiber gasket, which helps the filter plate to be sealed in the filter box to ensure that there is no metal loss. This product is mainly used in the purification process of aluminum and aluminum alloy production.