How to select molten metal filters? You need to understand which filter material is suitable for your metal casting and the characteristics of the filter.

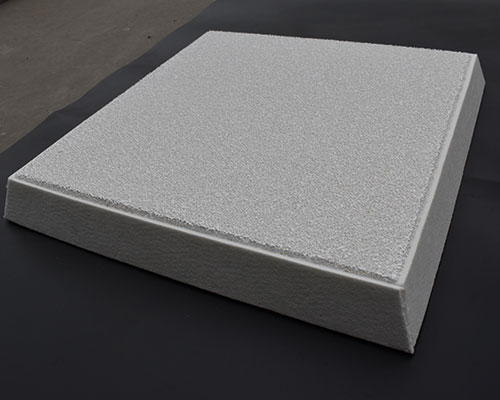

Foam ceramic is an ideal form of structure. The pore size and number of pores of this structure determine the resistance of the metal liquid through the filter. When non-metallic inclusions contact the filter medium, they are adsorbed and removed from the liquid metal. The pore size of the foam filter is usually expressed in PPi, that is, the number of holes per 25mm length. In general, this value represents the size of the filter before firing, and the size changes after firing, which is mainly the result of firing shrinkage. Materials with different compositions have different shrinkage coefficients.

1. The alumina ceramic foam filter works at 1100 degrees Celsius and is suitable for aluminum casting.

2. The zirconia ceramic foam filter works at 1700 degrees Celsius and is suitable for steel and stainless steel casting.

3. The silicon carbide ceramic foam filter works at 1500 degrees Celsius and is suitable for casting iron, copper, and copper alloys.

4. The zirconia-alumina ceramic foam filter works at a temperature of 1600 degrees Celsius, which is suitable for certain lower temperature steel requirements.

How To Select Molten Metal Filters

The following factors should be considered when select molten metal filters:

(1) Refractoriness. The filter should be able to work well at high temperatures above 1500″C.

(2) Chemical stability. The filter made of oxide should not chemically react with the elements such as Al and Ti in the nickel-based superalloy.

(3) Mechanical strength and hardness. In order to prevent damage caused by the impact of aluminum water and the installation process, the filter should have sufficient strength and hardness.

(4) High-temperature mechanical properties. The filter should have a certain strength at high temperatures, and the pouring process should not be deformed, cracked, or peeled under the impact of thermal stress.

(5) Thermal shock resistance. The filter does not burst after sudden contact with molten aluminum.