Hot top casting technology can overcome the disadvantages of conventional DC casting such as poor quality stability, difficult metal flow and control, and serious secondary oxidation, thereby improving the quality and production efficiency of ingots. Therefore, it is widely used in the casting industry in the aluminum casting industry. Pure aluminum and aluminum alloy ingots.

However, hot top casting is prone to the following problems in production:

1) The ingot crystal grains are coarse and uneven, which easily cause surface defects and mechanical properties of the extruded material during extrusion;

2) The production composition is complex and the crystallization temperature range is wide. When casting high-strength aluminum alloy ingots, it is easy to produce defects such as ingot cracking, uneven structure, and serious composition segregation, which affects product quality. In order to solve these problems, many new technologies have been developed in recent years.

For example, the air-slip casting technology developed on the basis of hot-top casting process equipment allows compressed air and lubricating oil to pass through the porous graphite ring embedded in the inner wall of the mold, thereby weakening the primary cooling strength and reducing the gap between the ingot and the inner wall of the mold. The friction force can produce ingots with smooth surface, fine grains and extremely thin surface segregation layer. However, the gas-slip casting equipment is complicated, the investment is large, and the requirements for process parameters such as oil and gas are strict.

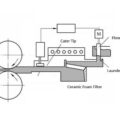

The casting method to improve the quality of aluminum and aluminum alloy ingots, the online degassing box and filtering equipment are installed between the melting furnace and the mold. After degassing and filtering, the molten aluminum enters the hot top and crystallizer through the inlet of the distributing launder, and starts the casting machine to start casting after reaching the predetermined liquid level.