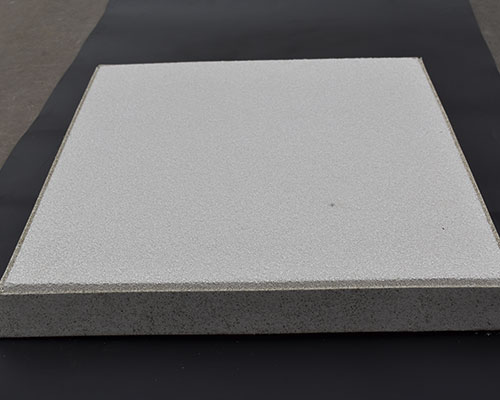

Molten Aluminum Filtering Equipment is an important part of aluminum casting, the ceramic foam filter is installed in the filter box as a filter medium. Foam ceramic filter plates have been widely used all over the world because of their convenient use, good filtering effect, and low price.

The ceramic foam filter can effectively remove the fineness of the aluminum water and reach the micron-level inclusions, so that the aluminum water enters a stable laminar flow, which is beneficial to the punching type. It has a unique mullite corundum structure, good mechanical strength and chemical stability, and excellent aluminum washing properties.

The use of alumina ceramic foam filters to purify liquid aluminum plates, strip aluminum foils, and their products (such as tanker blanks, exquisite decoration materials, PS boards, etc.) have brought huge benefits.

Molten Aluminum Filtering Equipment has the following obvious advantages for aluminum alloy profiles:

- Improve the extrusion survival rate: When the filter plate is used to purify 15% alloy extruded billets, we use specific die tracking and find that the extrusion speed and production efficiency has increased.

- The service life of the mold is prolonged and the number of mold repairs is reduced.

- The surface quality of aluminum profiles is significantly improved.

- The foam ceramic filter has the characteristics of large specific surface area, high mechanical strength, thermal shock resistance, etc.

- Purification of metallic liquids, removal of non-metallic impurities and gases.

- The filling of liquid metal is stable and the eddy current is reduced.

- Simplify the pouring system and improve the process yield.

- Refractory Molten Aluminum Filtering Medium can reduce the porosity of castings, optimize and refine the metal structure.

- Improve the surface quality and mechanical properties of castings, and reduce the rejection rate of castings.

- It can reduce the machining allowance, increase the service life of the tool, and reduce the casting cost.