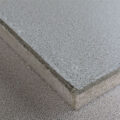

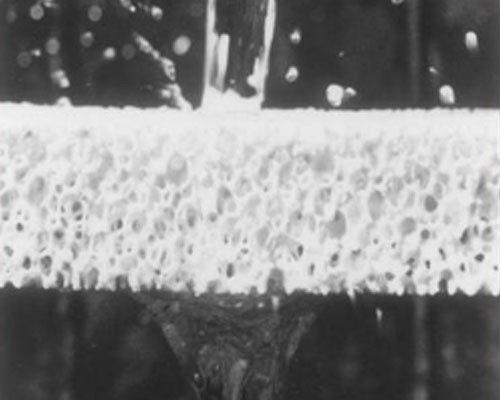

The ceramic foam filter has a network pore structure, has a certain strength, can withstand the pressure difference of the metal liquid level and the impact of the metal flow, but it is brittle and fragile. Because this material has a precise structure, uniform quality, and has a great surface area, so the ceramic filter molten aluminum filtration effect is excellent.

Ceramic Filter Molten Aluminum Filtration Advantages

Regardless of the huge benefits that the use of ceramic foam filter molten aluminum filtration, the aluminum foil and its products (such as can blanks, car finishing materials, PS printing plates, etc.), there are several obvious advantages:

1. Increase extrusion productivity: When using the filter plate to purify the 6063 alloy extruded billet, we have conducted a follow-up inspection on a specific die and found that the extrusion speed increased by about 20% and the productivity increased by nearly 15%.

2. Extend mold life and reduce mold repair times.

3. Reduce extrusion force: When the 6063 alloy melt was purified with a filter plate, it was found that the extrusion force was reduced by 3% more than the unfiltered one.

4. Significantly improve the surface quality of aluminum profiles. The use of ceramic foam filter plates to purify the aluminum melt has great advantages in reducing production costs and improving product quality.

In addition, the ceramic foam filter is used to purify the molten aluminum. The ceramic foam filter device is an ordinary steel shell lined with a prefabricated refractory material. It is installed between the casting launder and the casting machine. Therefore, there is no need to make major changes to the existing casting system, but only a small space. Moreover, a ceramic filter plate can effectively filter all the metals of one melting stage, and it is very convenient to remove or replace after use.