What is a Deep Bed Filter?

A Deep Bed Filter is a specialized filtration device used in the aluminum casting industry to purify molten metal. Unlike ceramic foam filters that rely on surface filtration, a deep bed filter utilizes a thick layer of ceramic media—typically alumina balls and gravel—to trap non-metallic inclusions throughout the depth of the bed. This “depth filtration” mechanism allows for the removal of extremely fine impurities (down to several microns), making it essential for high-end aluminum products like lithographic sheets, foil stock, and aerospace alloys.

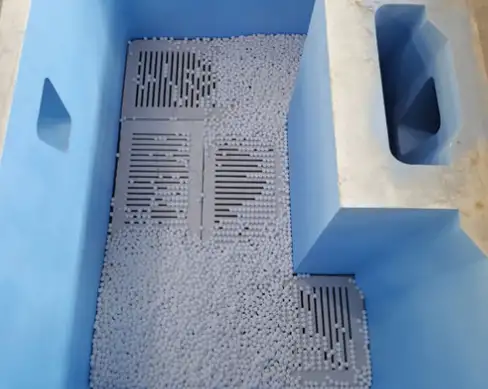

Deep Bed Filter structure for molten aluminum filtration showing alumina balls layers

Working Principle of Deep Bed Filtration

The efficiency of a deep bed filter relies on the complex path the molten aluminum must travel. As the metal flows through the packed bed of ceramic media, inclusions are captured via three main mechanisms:

-

Mechanical Interception: Large particles are physically blocked by the pores between the alumina media.

-

Sedimentation: Heavier inclusions settle onto the surface of the filter media due to gravity within the tortuous flow paths.

-

Surface Adsorption: Smaller, micron-sized inclusions are attracted to the ceramic surface through chemical affinity and physical forces.

The Importance of Media Layers

A typical deep bed filter is composed of multiple layers:

-

Top Layer: Coarse alumina balls to distribute the metal flow evenly.

-

Middle Layer: Medium-sized media to trap larger inclusions.

-

Bottom Layer: Fine alumina gravel to capture the smallest microscopic impurities.

Why Choose Deep Bed Filters for Aluminum Casting?

Compared to standard filtration methods, deep bed filtration offers distinct advantages for foundries:

-

High Filtration Efficiency: Capable of removing 95%+ of inclusions significantly smaller than the pore size.

-

Long Lifespan: Designed for continuous operation in large-scale casthouses.

-

Improved Metal Quality: Essential for minimizing defects in critical applications like can body stock and thin foil.

Deep Bed Filter Media Specifications

To ensure optimal performance, the quality of the filter media is paramount. Our deep bed filters utilize high-purity Alumina (Al2O3) balls and gravel, ensuring high thermal shock resistance and chemical inertness towards molten aluminum.

Technical Specifications

| Item | Specification |

|---|---|

| Model | DBF-500 |

| Application Flow Rate | Up to 500 kg/h (melt throughput) |

| Filtration Media | Multi-layer sintered ceramic (graded porosity) |

| Typical Inclusion Size Captured | ≥ 50 µm (macro), with high removal of >100 µm |

| Metal Retention (typ.) | < 0.8% by weight |

| Operating Temperature | 650 °C – 760 °C (suitable for common Al alloys) |

| Maximum Temperature | 820 °C |

| Unit Weight (empty) | ~120 kg |

| Dimensions (L×W×H) | 800 × 600 × 1200 mm (approx.) |

| Inlet/Outlet | 60 mm (flanged / customizable) |

| Pressure Drop (clean) | < 0.05 MPa |

| Filter Media Life | 200–600 melts (process dependent) |

| Materials of Construction | High-grade refractory steel + ceramic media |

| Controls (optional) | PLC + level sensors + pneumatic actuator |

| Safety Features | Thermal shield, pressure relief, emergency stop |

| Certifications | CE ready; ISO manufacturing standard (factory option) |

| Typical Packaging | Crated for sea/air freight |

Performance Data & Design Notes

-

Filtration efficiency and media life depend on alloy composition, melt cleanliness, upstream fluxing/degassing and pouring practices.

-

Designed for inline installation between pouring ladle and runner or prior to transfer to holding furnace.

-

Pressure drop measured at installation; always provide melt temperature and alloy for fine tuning.

Installation & Commissioning

-

Mount on rigid base with support for inlet/outlet flange alignment.

-

Pre-heat unit to operating temperature before melt contact to avoid thermal shock.

-

For continuous lines, integrate level sensors and automated valves to change cartridges without system downtime (if configured).

Maintenance & Spare Parts

-

Routine inspection after each shift; full media replacement typically every 1–4 weeks depending on throughput.

-

Carry spare sintered ceramic cartridges, gaskets, and flange bolts.

-

Typical maintenance time: 20–40 minutes for trained technician.

There are three main types of filters on the market today:

PLATE-TYPE FILTERING UNIT, tubular filter, and deep bed filter.

Ceramic foam filters and tubular filters in continuous casting and rolling production

It has been widely used and achieved remarkable results, but due to the ceramic filter plate

The effect is limited, and currently, it cannot meet the requirements of stable production of double-zero foil blanks, etc.

The need for end products, so continuous casting and rolling production of high-end product billets is mainly

The ceramic filter tube has been hoisted and preheated using ceramic tube filtration technology.

It is easy to crack during the process, and the crack is not easy to be found.

It is difficult to find the inclusions in the cast and rolled products, which brings great difficulties to the subsequent deep processing.

It is a big hidden danger, and it is easy to cause batch waste, the ceramic filter tube technology works

higher cost.

Learn from the deep bed process used in hot rolling and casting large slabs at home and abroad.

filter, to ensure the quality of high-end casting and rolling products, the deep test in continuous casting and rolling

bed filter. The filter medium of the deep bed filter is sintered by a special process

Alumina balls and grit, this depth filtration technology has been used in the foundry field

Recognized to meet the needs of high-end products. There are many in the world

Large aluminum companies: such as Alcoa (Alcoa), Alcan (Alcan),

Novelis has deep bed filter technology. But because of its

Large volume, installation, and replacement of filter media is time-consuming and labor-intensive, more suitable for large batches

The production of a single alloy [1] is difficult to meet the needs of continuous casting and rolling.

Characteristics, of the following problems, are found in the application process of continuous casting and rolling:

① It is difficult to replace alloy grades, and there are many wastes of alloy transfer;

② The heat storage capacity is strong, and it is not easy to adjust the temperature;

③ It isn’t easy to replace the filter medium, and the replacement cycle is long.

The principle of deep bed filters

Principle of deep bed filter

At present, the filter media of deep bed filters on the market are solid or liquid. According to the characteristics of the molten aluminum used for casting and rolling of the filter medium, the test

Choose alumina balls and grit as filter media. through filter media

The smaller the gap between, the thicker the filter medium, the lower the melt flow rate, and the lower the filtration efficiency.

The better the fruit. The speed at which the filter media captures inclusions is related to the

is proportional to the concentration in the body, that is:

( eN/et) z = KC ( 1 )

In the formula, N – is the amount of slag captured in the filter; Z – is the filter input

depth of mouth; C – concentration of slag inclusions in the melt; t – filtration time; K

– Kinetic parameters, which the following formula can express:

K = K0 ( 1 – N/Nm ) ( 2)

where K0 – kinetic parameter, and melt properties, between filter media

The size of the gap is related to the shape and size of the slag inclusion; Nm – captured by the filter

the maximum amount of slag inclusions.

When N→Nm, K→0, indicating the end of filtration, at this time in the melt

The following formula can express the slag inclusion concentration

C i = C0 exp ( – K0L /um ) ( 3)

In the formula, C I, C0 – the concentration of slag inclusions in the melt before and after filtration; L –

filter media thickness; um – flow rate of the melt in the filter media.

Available filtration efficiency η

η = 1 – C0 /C i = 1 – exp ( – K0L /um ) ( 4)

It can be seen from Equation 4 that the filtration efficiency is related to the thickness of the filter medium and

The flow rate of the melt in the filter medium is closely related, and the thickness of the filter medium is

The larger, the slower the flow rate of the melt in the filter medium, the greater the gap between the filter media.

Small, the higher the filtration efficiency, the better the filtration effect. Principle of deep bed filters [2]

As shown in Figure 1.