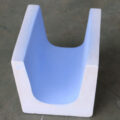

Refractory casting launder and trough is a silicic acid fiber product, which is mainly used in the distribution and transmission of molten aluminum with high thermal insulation requirements, such as active launder on casting and rolling, and distribution launder on the same level casting plate. Refractory Casting Launder is one of the basic equipment for aluminum alloy casting. The main function of the fixed launder with shell is to drain the molten aluminum from the mixing furnace to the casting machine.

The surface of the traditional launder is easy to stick to aluminum during the use process. When the operator cleans the launder, the working time is up to 30 minutes, and it is easy to cause damage to the castable. The high-temperature aluminum liquid penetrates into the castable and gradually deforms the steel plate of the shell. The time slot cannot be used normally. In addition, every time the convection trough is maintained, it is necessary to remove the castable and rebuild the shell steel plate after correcting it. The maintenance process consumes labor and materials.

In response to this problem, we renovated the launder system in April this year. The modified new type refractory casting launder has high overall strength and large unit volume density. The cavity of the launder is coated with high-temperature refractory coating and non-stick aluminum. The internal slag is easy to clean. Under high temperature conditions, there will be no damage or cracking within three years. There is no aluminum leakage at the bottom, which eliminates the potential safety hazards of aluminum leakage in the launder. The time to shut down and clean the launder is reduced by 20 minutes, which reduces labor intensity.

The launder lining is used in the aluminum processing industry as a working lining for the direct contact between the aluminum water transfer processing equipment and the aluminum water. The lining of the launder is made of fused quartz as the main raw material, and the excellent volume stability of the fused quartz material is utilized. The addition of anti-stick aluminum additives can prevent the penetration of molten aluminum, so that the entire material has excellent anti-stick aluminum properties.

Advantages of Refractory Casting Launder and Trough

1. Excellent heat preservation performance

2. High flexural and compressive strength

3. Excellent thermal shock resistance

4. The surface is smooth and non-stick aluminum

5. Good heat preservation performance