In the casting process of aluminum rods, the aluminum liquid in the melting furnace needs to degas and filter. Usually, it needs the help of the degassing system and filtering system. And then the aluminum liquid flows into the aluminum casting system through the refractory launder, and casts into aluminum rods.

Refractory Launder for Molten Aluminum

Although the molten aluminum will be drossed before flowing out of the mixing furnace, it is difficult to clean it thoroughly, so it will inevitably contain impurities such as calcium oxide. When the aluminum liquid flows in the refractory launder, the surface aluminum liquid is in contact with air over a large area and is oxidized into aluminum oxide. It will seriously affect the quality of the aluminum rods cast, and these impurities must be cleaned up.

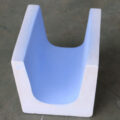

The molten aluminum flowing out of the furnace enters the sedimentation tank through the refractory trough. Because the casting launder dam is provided in the middle of the sedimentation tank, the bottom of the baffle is higher than the bottom of the sedimentation tank and lower than the bottom of the flow channel, so the aluminum liquid will flow downward.

Through the opening below the launder dam, it then flows out from the flow channel on the other side of the settling tank. In this way, the liquid aluminum forms a “U” shaped flow trajectory in the sedimentation tank. It increases the residence time in the aluminum liquid sedimentation tank, allowing impurities such as calcium oxide mixed in the aluminum liquid to have sufficient time to stand still.

Refractory Trough Dam

Because the density of impurities is less than the density of the aluminum liquid, the impurities will gradually float to the surface of the molten aluminum, and the aluminum oxide formed by the contact between the aluminum liquid and oxygen also floats on the surface of the aluminum liquid.

Due to the presence of the launder dam, these two types of impurities are blocked on the side of the sedimentation tank and do not enter the subsequent casting, ensuring the quality of the aluminum rod. These impurities can sink to the bottom of the pool after the aluminum liquid has flowed out and be cleaned up uniformly. It is more convenient to clean impurities than traditional casting, while reducing a lot of labor.