Online degassing devices are the key research and development objects of major aluminum melting and casting plants. There are many types. Typical examples are MINT and other devices that use fixed nozzles and SNIF, Alpur and other devices that use rotating nozzles. Since the end of 1980s, many manufacturers in my country have successively purchased some MINT, SNIF, Alpur and other devices from abroad. Since then, based on the introduction of equipment, they have also developed a variety of degassing equipment by themselves, such as Southwest Aluminum’s SAMRU, DFU, DDF and many more.

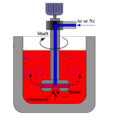

These degassing devices all use N2- or Ar as the refining gas, which can effectively remove the hydrogen in the aluminum melt. For example, adding a small amount of Cl2, CCl4 or SF6 to the refining gas can also remove alkali metals and alkaline earth metals in the melt. However, the above-mentioned degassing device has a relatively large volume, a large amount of dry material is placed between casting passes or heating and heat preservation are required, and the operation cost is high.

The new development direction of the degassing device is to continuously improve the degassing efficiency, reduce the operating cost, such as the online degassing devices developed by AdTech.

AdTech online degassing equipment has an ultra-long life furnace body using a new type of high-silicon melting material manufacturing technology. The degassing rotor, heater protection sleeve, and thermocouple protection sleeve are all made of silicon nitride (Si3N4) ceramic manufacturing technology. It can meet aluminum products with high added value and high technical performance requirements. On-line degassing equipment is installed between the furnace and the casting machine, and its role is to remove the hydrogen and other residues contained in the molten aluminum and its alloys that affect its quality and mechanical properties. It has dual functions: processing and heating, and is mainly used for the purification of the melt in the production of high-precision aluminum products.