Aluminium alloy melt refining flux dosage: when smelting aluminum alloy scrap, the quality of the scrap is different, and the amount of covering agent and refining agent are also different.

The following methods are commonly used methods for producing aluminium alloy melt refining flux

1. The melt is refined in a ladle. First, place a pack of flux in the ladle, then inject the melt and stir thoroughly to increase the contact area between the two.

2. The melt is refined in an induction furnace. The flux is fed into the induction furnace, and under the stirring action of the induction magnetic field, the flux and the melt are fully mixed to achieve the purpose of refining.

3. Refining in a ladle, or mechanically dispersing the flux in the melt with a stirrer in a furnace.

4. The melt is refined in a magnetic field stirring device. This method relies on the action of electromagnetic force to continuously deliver the melt to the flux-metal interface to achieve active contact between the aluminum melt and the flux. The higher the melt speed, the better the refining effect.

5. Electric flux refining. This method is to continuously refine the flux by applying an electric field (at the interface of the metal flux) to the flux layer.

Flux Removes Non-Metallic Inclusions, the dry ash-like slag produced is easily separated from the liquid metal.

Therefore, slag skimming is promoted, and metal loss due to aluminum staying in the scum is reduced. Molten aluminum refining is specially developed for environmental protection.

It is dust-free during use and emits low smoke during use. Compared with powdered flux, granular flux can be used in a reduced amount.

Instructions for use: The best application of molten aluminum refining is to add it to the pouring stream during the process of filling and transporting ladle or crucible.

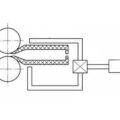

Alternatively, it can be added to the metal surface after the transfer is complete. If FDU degassing is used, the flux will react easily, resulting in shallow and dry scum.

If the degassing process is not carried out, the flux must be stirred vigorously in a preheated ladle with holes until it reaches a dry slag.

After the reaction is complete, use appropriate skimming tools to carefully remove the scum.