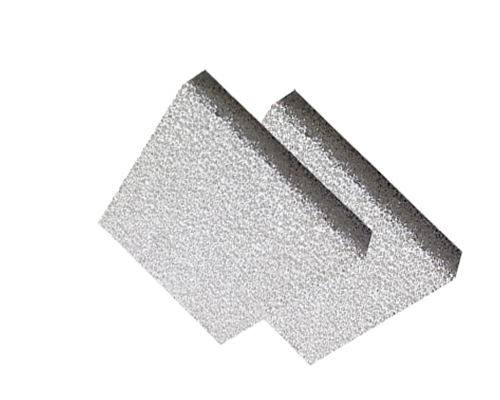

Aluminum Casting Ceramic Filters are increasingly used in the aluminum rod and ingot casting process in the aluminum industry. They are special filters made of materials such as alumina to give them structural stability and ensure thermal shock resistance.

Aluminum Casting Ceramic Filters can remove oxides on the aluminum surface to improve casting quality. More and more aluminum foil and aluminum foil manufacturers are using these filters.

Adtech is one of the largest ceramic foam filter product suppliers in India and the global industrial market. The company provides these high-quality filters to customers involved in aluminum sheet and aluminum sheet production. Alumina Ceramic Foam Filters is available in all common sizes: 7″, 9″, 12″, 15″, 17″, 20″, and 23″. We offer the whole range of porosities from PPI 10 up to PPI 60 (PPI = pores per inch). Custom-made cut-to-size filters are also possible.

Alumina ceramic foam filters are mainly used in aluminum production and aluminum alloy purification processes. With the increasing requirements for high-quality aluminum products, the application of alumina ceramic foam filters will be more extensive.

Generally speaking, the selection of alumina foam ceramic filters should comprehensively consider factors such as the quality requirements of the finished product, the circulation capacity of the cast aluminum cans, the total cast aluminum filtration volume, and the aluminum liquid cleaning volume.

Use of Aluminum Casting Ceramic Filters

1. Clean the CFF filter box.

2. Carefully put the filter into the filter housing and press the gasket around the filter to prevent molten aluminum from flowing out from the side.

3. Evenly preheat the filter housing and filter plate to make it close to the temperature of the molten aluminum casting.

4. Pay attention to the change of the liquid aluminum power head, the normal initial pressure head is 75-150mm. When the alumina liquid starts to pass, the indenter will drop below 25mm, and then the indenter will gradually increase.

5. After filtering, remove the filter plate in due course and clean the filter housing.