Temperature control and melt purification are important for Aluminum Production Process.

In aluminum casting production process, 20%~30% solid cold material is generally added for batching. First, add the aluminum ingot for remelting or the first-grade scrap of this alloy, then add the intermediate alloy, and finally inject the electrolytic aluminum liquid. The high-temperature heat of the electrolytic aluminum liquid is used to quickly melt the solid materials added into the furnace, and the temperature of the electrolytic aluminum liquid can be reduced, and at the same time, the nucleation rate of the molten metal is increased.

Temperature Control

Melting temperature: The normal smelting temperature is controlled at 740~780.

Refining temperature: control the degassing and slag removal at 740~760.

Converter temperature: The temperature of the molten aluminum in the smelting furnace is kept within the range of 740~760 before the converter can be started.

Casting temperature: usually controlled in the range of 690~740.

Melt Purification

The electrolytic aluminum solution contains metal impurities such as silicon, iron, sodium, calcium, phosphorus, boron, titanium, vanadium, and zinc, and non-metallic inclusions such as aluminum oxide, aluminum fluoride, aluminum carbide, and aluminum nitride. The gas content is high, and the hydrogen content can reach 0.60~1.29mL/(100gAl). The presence of gas in the melt and various metallic and non-metallic inclusions will cause structural defects in the ingot, which in turn affects the structure and performance of processed products. Therefore, when using electrolytic aluminum liquid ingredients to produce aluminum alloy slab ingots, more stringent purification treatment processes must be adopted for the aluminum melt to ensure the purity of the aluminum melt.

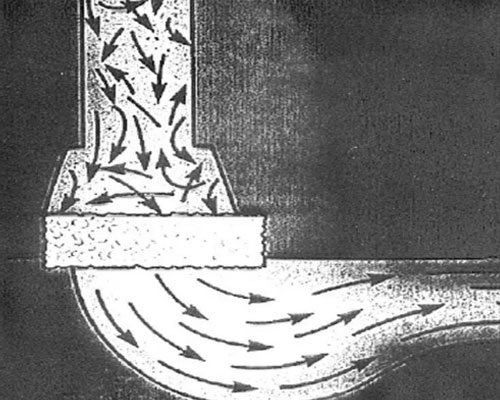

Ceramic Foam Filter Product is suitable for molten aluminum purification in the aluminum production process, such as casting aluminum rods, aluminum ingots, aluminum plates, and other aluminum alloys. Since the ceramic foam filter is used in the casting process to filter the metal oxides and other solid slag contained in the molten metal, thereby improving the quality and yield of aluminum alloy, the use of ceramic foam filter promotes the technological progress of the foundry industry.