The principle of SNIF purification is to blow inert gas or inert gas containing a small amount of chlorine into the melt. During the purification process, the aluminum alloy melt enters the first purification zone through the population of the device, is purified by the rotating nozzle, and then enters the second purification zone through sections for secondary purification. The melt flows back to the front of the device through the graphite tube at the bottom of the furnace. The storage compartment is finally replaced through the upper outlet. The hydrogen content is reduced to 0.1-0.5ml/100gAl, the removal rate of inclusions above 50um is above 80%, and the amount of alkali metals is reduced to below 5ppm.

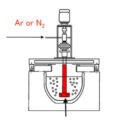

Apmr method: A processing box is placed between the static furnace and the casting and rolling mill, and the aluminum alloy melt is processed by active gas or inert gas in the processing box to remove hydrogen and other impurities. The special structure of the Alpur rotating diffuser, that is, the rotor, can cause a large number of dispersed bubbles in the blown gas to achieve a better purification effect. Its hydrogen removal rate can reach 70%.

MINT is suitable for online purification process in aluminum alloy processing and production, and has a good purification effect on hydrogen, non-metallic inclusions and alkali metals in aluminum alloy melt. The principle of this method is: the melt enters the cylindrical upper part of the degassing chamber in a tangential direction and flows downward in a spiral shape, and the gas is injected into the degassing from the high-pressure nozzle at the bottom of the degassing unit. It is dispersed in the entire melt in the form of small bubbles, and the contact time between the aluminum liquid and the bubbles is extended by making the aluminum liquid flow fully. The degassed molten aluminum is filtered through a ceramic foam filter. This method utilizes the comprehensive effect of “jetting inert fine bubbles to remove hydrogen + ceramic foam filtering inclusions”, and the effect of removing impurities is better. The hydrogen removal rate reaches 54%. After purification, the hydrogen content in the aluminum alloy melt can be reduced to 0.12ml/l00gAl, the removal rate of inclusions above 50um reaches 80%, and the amount of alkali metal Na drops below 3ppm.