In aluminum and aluminum alloy melts, refining agents can remove metal impurities, oxides, and other oxide inclusions from the melt through physical, chemical, or physical-chemical interactions. The impurity removal ability of the refining agent is determined by the adsorption and dissolution of the refining agent on the oxide inclusions in the melt and the chemical effect between the refining flux and the impurities in the melt.

The smaller the interfacial tension between the refining agent and the inclusions, the better the adsorption of the refining agent and the stronger the removal of impurities. Some metal impurities in the aluminum melt are difficult to remove during the smelting process. These impurities can only be strictly limited in the raw materials, such as silicon, iron, and other impurities, while the other metal impurities, such as calcium, zinc, and other metals. They will all have an adverse effect on the performance of aluminum alloy. These harmful impurities should be removed before smelting or casting. The traditional method is to add a refining agent in the furnace during smelting, so it is called “refining”.

One of the common features of the existing aluminum refining agents is that their application range is narrow and their functions are single. It is necessary to put in several different refining agents to achieve different purposes. And often the effect is not significant, or harmful to the cleanliness of the melt or the environment, and there are various problems in varying degrees. Therefore, the research and development of a new refining agent integrating multiple functions will be one of the future development directions.

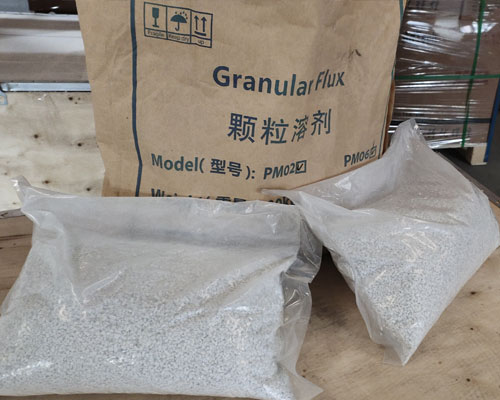

AdTech supplies refining flux, slagging flux, furnace cleaning agents, and covering flux, and their functions are different.

- When the temperature of the aluminum alloy reaches about 660-720 degrees, add the refining agent. Press the tool to the bottom until no bubbling occurs. It is mainly used to remove hydrogen from the aluminum liquid.

- Add slagging agent after refining, remove the slag after fully stirring with tools, mainly used to remove impurities in the aluminum liquid.

- After the slag is cleaned, spread covering agents such as expanded perlite and expanded graphite on the surface to prevent the hydrogen in the air from entering the aluminum liquid and keeping it warm.

- After the melting of aluminum and aluminum alloys, the furnace cleaning agent cleans the furnace wall.