The cast house ceramic foam filter has been used to remove impurities from aluminum liquids for over 30 years. After successful use in industrial practice, it quickly replaced the glass filter, microporous ceramic tube, alumina ball, and other filter elements.

The cast house ceramic foam filter has a lattice structure and has a certain strength, can withstand the pressure drop of the metal liquid level and the impact of metal flow, but it is fragile and brittle because the material has a precise structure and quality, and has a large surface area, so the filtering effect is excellent.

The ceramic foam filter plate for purifying molten aluminum has tremendous advantages in terms of reducing production costs and improving product quality.

In addition, the ceramic filter plate is used to purify liquid aluminum, and the device is a conventional steel shell lined with a prefabricated refractory brick mat. It is formed horizontally in the metal flow cell, that is, between the flow hole and the casting well. Thus, there is no need to make major changes to the existing casting system, only a small space is required. What’s more, the filter plate can effectively filter all the metal from one melt, and it is very convenient to take out or replace it after the end of use. It is also suitable for horizontal or vertical casting systems.

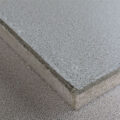

Cast House Ceramic Foam Filter Molten Metal Filtration Mechanism

1. The effect of a sludge layer or filter cake layer with deposition of particles in the melt and entwined and twisted mesh connections improves the ability to capture phase particles.

2. The rough surface formed by the gap of the mesh truss surface increases the interface between the liquid aluminum flow and the solid ceramic surface, facilitating the penetration of particles into the liquid aluminum flow.

The direction of the auxiliary flow is more irregular, which facilitates the collection and deposition of solids.

3. Due to microscopic cracks and pinholes, a fluoride flux with a strong affinity for particles such as Al2O3 is pre-deposited on the surface of the mesh frame.

The whole filter cake effect and strong chemisorption force increase the ability to capture trapped heterogeneous particles.