By using Ceramic Foam Filters for Cast Aluminum, the waste aluminum can be melted in a molten salt bath, and after the molten aluminum is precipitated in the holding furnace, the molten aluminum can be separated from metal impurities and solid particulate materials. For example, aluminum scrap from automobile dumps usually contains more than 50 wt% impurities.

Molten aluminum can flow through the replaceable ceramic foam filter unhindered, and all solid particles are blocked. The aluminum to remove solid impurities continuously or with a certain charge from the filter chamber, enters the holding furnace or directly into the electrolytic tank for electrolytic purification.

After all the aluminum has passed through the suspension, it is passed through a filter. Although the molten aluminum that must be filtered contains only a few solid particles, the main part of the solid contaminants is provided by the molten salt to the ceramic filter. The particles form a cake there, which can be removed with or from the ceramic filter after the charge has passed.

The purified molten salt of the solid particulate matter is returned to the melting furnace, where it can be sent to the next batch of aluminum scrap.

Advantages of Ceramic Foam Filters for Cast Aluminum

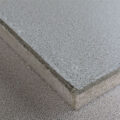

- Reduce the gas and inclusions contained in the casting, reduce the turbulence of the molten metal when filling the mold, reduce the surface defects in the casting, and significantly reduce the scrap rate of the casting.

- Increase the compression and sealing of the casting, increase the elongation and tensile strength of the casting, improve the surface finish of the casting, improve the fluidity of the molten metal, increase the filling ability, and feeding ability of the melt.

- Simplify the casting system, reduce the length of the lateral flow channel, and increase the casting output.

- Reduce processing time and tool wear, improve the surface quality of castings.

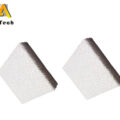

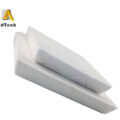

- Ceramic foam has high mechanical strength, chemical stability, high thermal shock resistance, and liquid metal flow shock resistance even under high-temperature environment. No slag or broken during the work process to ensure the quality of the molten metal and stable chemical composition.

- With a large and stable metal flow rate, even if the content of inclusions in the molten metal is high, it will not block the ceramic foam filter.