Regardless of the filter used, care must be taken to ensure that the filter is not affected by excessive vibration or changes in the metal level. These interferences will cause the release of inclusions, which may eventually lead to inclusions in the finished product. Good process control downstream of the final aluminum alloy filtration equipment […]

SEO

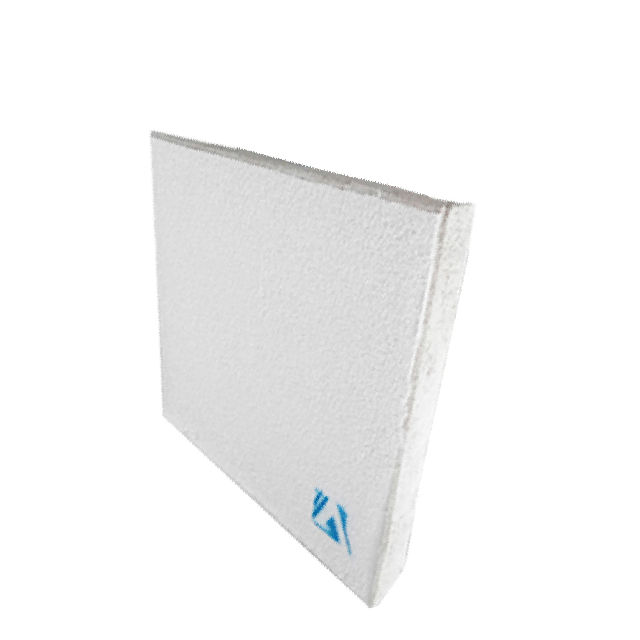

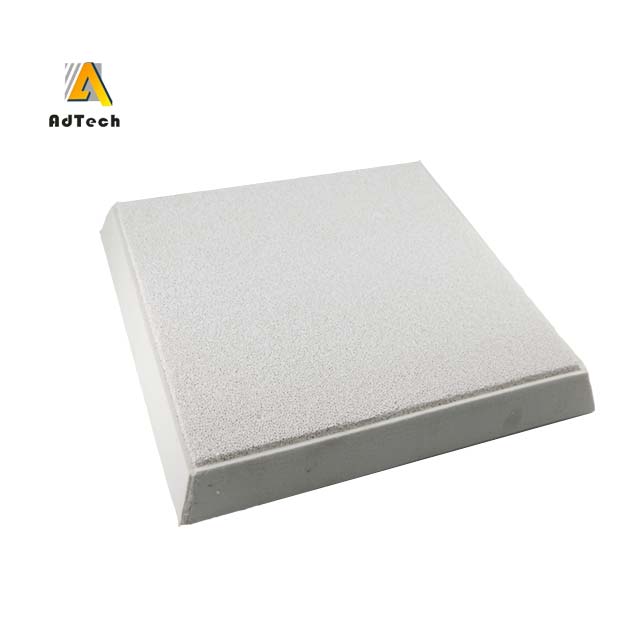

The final molten aluminum filtration step is usually a ceramic foam filter (CFF). This is a single-use disposable filter made of hard porous ceramic foam with strictly controlled pore size. Due to their simple operation and short-term good results, these are usually the only filtration equipment in many foundries. The three key parameters of CFF […]

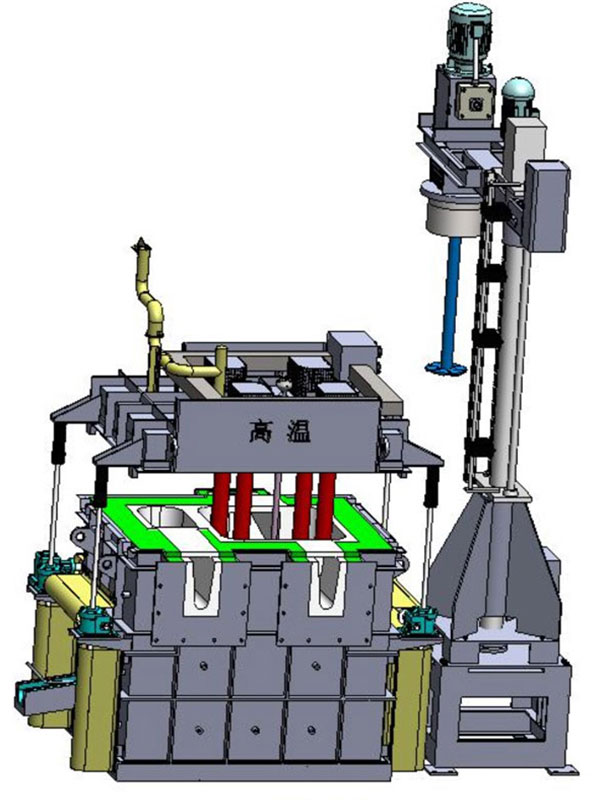

There are many different types of degassers, but most aluminum foundries rely on rotating rotor degasser. The rotor injects chemically active reactants (usually chlorine or solid salt flux) mixed with a carrier gas (such as argon or nitrogen) into fine bubbles and enters the molten metal. The key to operating such equipment for optimal efficiency […]

AdTech provides a high-efficiency ceramic foam material for filtering molten metal, especially molten aluminum. The ceramic foam material is characterized by having a three-dimensional network structure with a plurality of interconnected voids surrounded by the net of the ceramic material with ceramic fibers. The air permeability of the filter is 400 to 8000×10 -7 cm […]

AdTech provides a high-efficiency ceramic foam material for filtering molten metal, which is characterized by improved strength and reliability. The filter of the present invention is prepared by impregnating an organic foam material with an aqueous ceramic slurry containing ceramic fibers. The ceramic foam filter has the advantages of high strength, high reliability and low […]

Today’s aluminum industry requires strict metal quality standards to prevent parts failure in key components of automobiles, airplanes, and machinery. Filtration is the last online metal treatment performed before molten aluminum casting. To control the flow rate and reduce the level of inclusions entering the filter system, many other upstream processing stages are required, all […]

The porous ceramic filter medium has a primary porous structure imparted by the foam macrostructure, which is the exoskeleton of the polyurethane precursor, and is replicated by coating with slurry, followed by drying and firing. The primary pore size is usually 3 holes per linear inch (ppi) to 100 ppi, more preferably 20 ppi to […]

Aluminum is a very active metal, which easily reacts with water vapor during the smelting process to generate hydrogen and oxide inclusions (Al2O3). These non-metallic inclusions are very harmful to the performance of aluminum products. Therefore, the purification of aluminum melt is one of the main ways to improve the quality of aluminum products. The […]

Separating oxides and other slag from molten aluminum is the most important function of the aluminum melt refining agent. The chemical properties of aluminum and its alloying elements are very active, and oxides, nitrides, carbides and sulfides are easily formed. When aluminum ingots and scrap aluminum are melted, these impurities are brought into the solution. […]

Online rotor degassing device is one of the best degassing technologies for molten aluminum, the first choice for high-end aluminum castings. The box-type online rotor degassing device is usually installed between the furnace discharge port and the filter box. The melt flows into the box of the degassing device, and the inert gas is broken […]