A slagging process sprays the metal casting flux onto the surface of the molten metal, so that the flux and the slag are mixed. The aluminum casting flux reacts with the fine aluminum particles contained in the slag. The reaction generates reaction heat, which heats the slag to enhance the fluidity of the metal contained […]

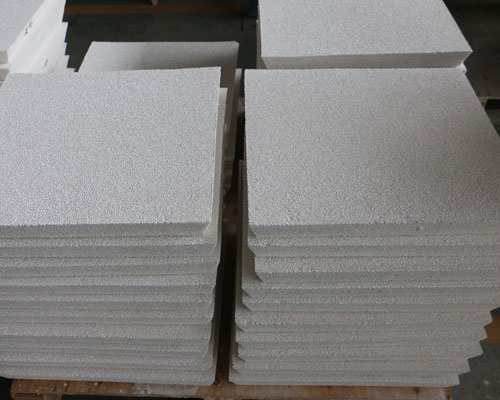

The application of Foam Ceramic Filter for Metal Casting has various advantages. One is that the flow of metal is effectively calmed down due to the complex 3D structure of the filter, thus sand erosion is reduced and the filling of mold is improved. Another advantage is that the ceramic filter removes solid inclusions like […]

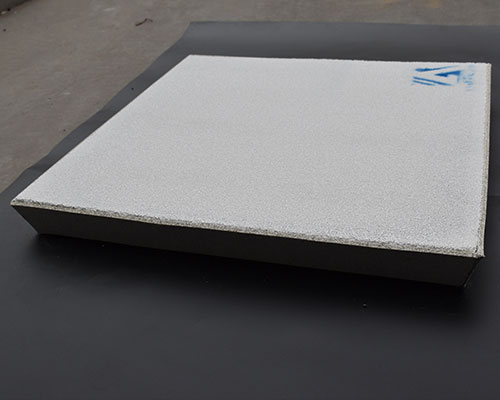

When choosing Porous Alumina Ceramic Foam Filters, it is more necessary to evaluate the useful value of the foam more closely than the calculation of the appearance and porosity of the product. The uniform state of the grid can be checked on the outer surface of the ceramic filter plate, and the uniform state of […]

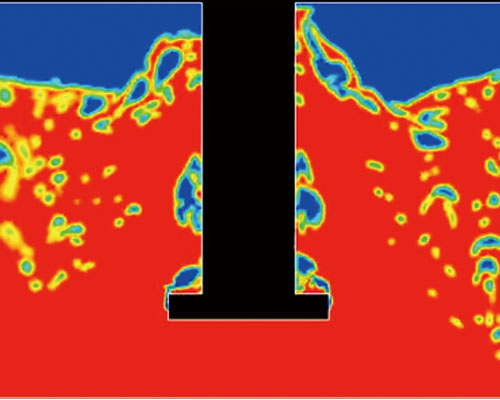

In order to get the molten metal cleanliness. First, it must be ensured that the melting and holding practices used before casting are as close to best practices as possible. The higher the cleanliness of the molten aluminum before the metal degassing filtering operation, the higher the cleanliness after treatment. It is necessary to combine […]

The porous ceramic foam material is known to be particularly useful in filtering molten metal. This porous ceramic foam material is particularly useful for filtering molten metal for a variety of reasons, which are the excellent filtration efficiency, low cost, ease of use, and ability to use same on a disposable, throwaway basis. Molten metal, […]

Covering flux for Aluminum smelting has a good protective effect. Due to the abundant raw materials, simple process requirements, and low cost, the covering flux for aluminum smelting can be widely used in the smelting process of metal aluminum and its alloys. Metal aluminum and its alloys have been widely used in various aspects due […]

It is important to have a Flux in Recycled Aluminum that separates the metal from the waste. The secondary aluminum industry is concerned with the production of aluminum from slag, scum, and waste. Therefore, the recycled aluminum contains impurities and oxides, which must be separated during the melting process to separate valuable metals. The waste […]

Foundry Filter for Molten Aluminum plays a very important role in improving the quality of castings. It can effectively filter liquid-solid non-metallic inclusions in molten metal once or twice, thereby reducing slag holes, improving the mechanical properties of castings, reducing machining allowances, improving surface finish, and prolonging the service life of castings. If the molten […]

Aluminum Metal Melt Filter is based on polyurethane foam as a carrier, immersed in a coating made of ceramic powder, binder, sintering aid, suspending agent, etc., to extrude the excess coating. The ceramic coating is uniformly coated on the carrier frame to form a green body, and then the green body is dried and baked […]

Aluminum degassing method is to spray inert gas into molten aluminum to achieve the purpose of removing hydrogen. In addition, aluminum degassing method is also considered to be a very effective way to float impurities. Two main theoretical models have been proposed to explain the principle of degassing. The macro model assumes that the removal […]