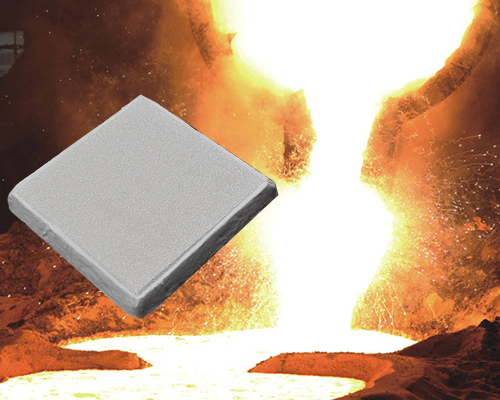

Ceramic filter is the key for aluminum alloy purification and refining in the process of aluminum scrap smelting. Aluminum casting ceramic filter can remove non-metallic inclusions in aluminum alloy melt. Treat with flux in the furnace. The ceramic foam filtration technology outside the furnace has become an important method for the purification of molten aluminum.

The ceramic casting filter is specially designed for the production of high-quality casting products in aluminum casting workshops. It can reduce waste caused by impurities, reduce costs due to impurity defects, achieve faster extrusion or hot rolling speeds, increase productivity and easy replacement of alloys.

A large amount of aluminum scraps are generated during the production of automotive aluminum alloy parts. The usual treatment methods for scrap aluminum are smelting and recycling.

Ceramic foam filters are used to filter liquid impurities in smelting aluminum alloys to meet the production of aluminum alloy precision castings with high added value and high technical performance for aviation and transportation.

Storage of ceramic foam filter for aluminum casting: It should be stored in a ventilated and dry environment to prevent moisture, and no objects should be placed on it.

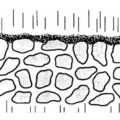

When the fluid passes through these micropores, the suspended matter in the fluid, colloidal particles, polymer organic matter, etc. are captured or adsorbed in the micropores in the road, so as to achieve the effect of uniform purification and filtration.

Ceramic Filter for Aluminum Alloy Purification Effect

1. Effectively remove harmful impurities such as bubbles, oxidized ash, and various inclusions in the aluminum melt, fundamentally eliminate pores, slag holes, and bubbles in the castings, greatly improve the yield of castings, and improve the inherent performance and appearance of the quality of the casting.

2. Improve the mechanical properties of the casting: it can increase the hardness of the casting, the surface hardness is uniform, and the bending strength of the casting can be improved.

3. Change the processing performance of castings and improve processing efficiency.