Non-metallic inclusions in castings are the main factor leading to casting defects. They affect the surface finish, mechanical and processing properties of castings, and lead to an increase in the rejection rate. Ceramic foam filter for aluminum casting quickly replaced various filter carriers, such as glass cloth, microporous ceramic tubes and alumina balls, and was widely used in primary aluminum production and aluminum processing industries.

The ceramic foam filter product accurately removes inclusions and reduces turbulence, thereby realizing a fast and stable molten metal filling flow rate, thereby improving the quality of castings.

Ceramic filter for aluminum casting is very important to the quality of aluminum melt, which greatly affects the subsequent processing performance and the quality of the final product. Therefore, all countries in the world very much hope the purification of aluminum melt.

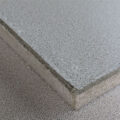

The ceramic foam filter has a mesh structure, has a certain strength, and can withstand the influence of the pressure difference of the metal liquid surface and the metal flow. Because the material has a precise structure, uniform quality and large surface area, the filtering effect is excellent.

The cast ceramic filter is composed of many uniform and countless micropores. When the molten aluminum passes through these small holes, the suspended matter is trapped on the surface of the filter medium, and the fluid passes through the microporous channel to produce various physical effects, thereby achieving the effects of mechanical filtration, purification, diffusion and fluidization.

The porosity specifications and sizes of cast ceramic filters are diverse, and are suitable for almost all aluminum processing industries, such as electrolytic aluminum plants, plate and strip processing plants, foil processing plants, pipe and wire processing plants, and recycled aluminum ingots.

The cast ceramic filter effectively removes various inclusions in the aluminum melt through filtration, which greatly improves the cleanliness of the metal, which is beneficial to improve product quality and reduce costs. The productivity has been improved to varying degrees, the operation is easy, and the process is easy. Control does not require excessive investment and is worthy of promotion and application.