Ceramic Filters Material plays an important role in the production of aluminum alloy casting industry. It can improve the surface quality, product performance and microstructure of aluminum, and increase the yield of aluminum.

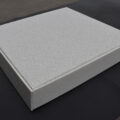

Gently put the alumina ceramic foam filter into the filter box. Then press the gasket around the filter plate by hand. Prevent lateral flow of molten aluminum. Preheat the filter box and filter plate evenly. In order to make the temperature close to the temperature of molten aluminum. Preheating can remove moisture and facilitate rapid filtration. The preheating method can be electric heating or gas heating. Usually, the preheating time is 15-30 minutes.

The ceramic foam filter has a unique three-dimensional interconnected curved pore network skeleton structure, its open porosity can reach 80%-90%, and has the following three filtration and purification mechanisms: one is mechanical interception, the other is distillation scum, and the third is Deep adsorption. Through these three filtering and purification mechanisms, the large inclusions of liquid metal and a large number of small floating objects can be effectively filtered out to tens of microns, thereby reducing the rate of casting rejects and welding repair rates.

In addition, it can also simplify the pouring system and improve the metallographic structure, thereby increasing the output and productivity of the casting process, and improving the quality and performance of the castings. Therefore, the foam ceramic filter has a good application prospect.

Ceramic Filters Material has the advantages of large filtration area, good thermal shock stability, high chemical stability, good metal erosion resistance, and good filtration efficiency.

Therefore, as a new type of high-efficiency filter in the metal melt filtration and purification technology, people’s attention has been paid.

At present, its application range has been extended to precision casting, cast steel industry and foundry industry. Foam ceramic filters can improve the mechanical properties of castings, reduce the rate of casting rejects, increase the rate of finished castings, and extend the service life of metal cutting tools.

Due to the closed cells in the ceramic foam, its thermal efficiency is reduced and the heat transfer in the convection process is reduced, so that the ceramic foam has the characteristics of low thermal conductivity and good thermal shock resistance. It is an ideal heat-resistant material.