The key to the degassing of molten aluminum is the quality of degassing, and in order to minimize the hydrogen in the molten aluminum, it is necessary to provide a method for degassing the molten aluminum, which can better remove the hydrogen in the molten aluminum.

Because the performance of aluminum alloy wire is incomparable with ordinary steel core aluminum stranded wire, aluminum alloy wire is currently widely used in the world, and its consumption has accounted for 20% of the total amount of wires. The steel wire is very brittle, partially broken, and has poor bending performance. The main reason is that the magnesium in the aluminum alloy liquid changes the dissolution rate of hydrogen in the aluminum liquid and improves the solubility of hydrogen, so that the hydrogen in the aluminum alloy liquid is much higher than that in the ordinary aluminum liquid. If the hydrogen and impurities in the aluminum alloy liquid are not removed, the bending, torsion and other mechanical properties of the aluminum alloy wire will not meet the quality requirements.

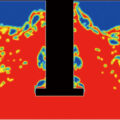

In view of the above problems, AdTech provides an online aluminum degassing system, which can degas more effectively and improve product quality. The inert gas is introduced into the molten aluminum in the ladle and put into the rotor, and the rotor is rotated in the molten aluminum at a speed of 400~500r/min. The aluminum degassing system can remove hydrogen and inclusions in molten aluminum.

The principle of the aluminum online degassing system is that the solubility of hydrogen in aluminum depends on the partial pressure of hydrogen in the gas phase in contact with the aluminum melt. When the hydrogen partial pressure corresponding to the hydrogen content in the aluminum melt is greater than the hydrogen partial pressure in the actual gas in contact with the aluminum melt, the hydrogen in the aluminum melt will diffuse into the gas phase to achieve hydrogen removal.

Therefore, in order to remove as much hydrogen as possible from the aluminum melt with as little inert gas as possible, the on-line inert gas removal of hydrogen should follow the following principles:

- The lower the content of hydrogen and oxygen in the inert gas, the better.

- The more bubbles formed by blowing inert gas into the melt, the smaller the bubbles and the better the dispersion.

- The longer the bubbles stay in the aluminum melt, the better.