According to the different degassing mechanisms, the molten metal degassing refining method of aluminum alloy melt can be divided into partial pressure difference degassing, compound degassing, electrolytic degassing, etc.

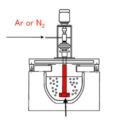

The partial pressure difference molten metal degassing refining method is to place the gas-dissolved metal in a vacuum with a small hydrogen partial pressure, or to introduce an inert gas into the melt to provide the driving force for dehydrogenation. In industrial production, it is usually to pass N2, Ar and other emotional gases into the melt, or press the gas-producing flux into the melt. Since there is no hydrogen at all inside the bubble, that is, the partial pressure of hydrogen is zero, and the partial pressure of hydrogen in the melt around the bubble is greater than or equal to zero. Under the effect of the hydrogen partial pressure difference between the inside and outside of the bubble, the dissolved hydrogen atoms diffuse to the melt-bubble interface, where they recombine into hydrogen molecules into the bubble, and then the hydrogen molecules float together with the bubble to the surface of the melt and escape. This process will continue until the partial pressure of hydrogen inside and outside the bubble is equal.

The compound molten metal degassing refining method is to add a certain substance that can form hydrides and nitrides with gas into the flux, such as adding Li, Ca, Ti, Zn and other active metals to form LiH, CaH, TiN, ZnN, and other compounds to melt the metal A method of removing gas from the body. These formed compounds have low density and are mostly insoluble in molten metal, and are easily eliminated by slag removal and refining. The hydrogen and oxygen dissolved in the molten metal sometimes interact to form neutral water vapor, which can also achieve the purpose of degassing.

The electrolytic molten metal degassing refining method uses a pair of electrodes inserted into the molten metal, and the surface is covered with covering flux. Or the metal melt is used as one electrode, the other is inserted into the flux, and then direct current is applied for electrolysis. Under the action of the electric field, the H in the metal tends to the anode, neutralizes the charge and polymerizes into hydrogen molecules, and then escapes. Other negative ions in the metal release charges on the cathode, then gather and float up and stay in the flux, and are combined into slag to be removed. Practice shows that this method can not only remove gas, but also remove slag, and can be used for the refining, degassing, and slag removal of aluminum and its alloys.