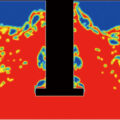

Degassing System for Romania Aluminium can break up large bubbles of incoming inert gas into smaller ones and disperse them throughout the metal solution.

By reducing the bubble diameter, the surface area of the inert gas increases sharply, so that more inert gas surface contacts with hydrogen and impurities in the metal liquid and removes hydrogen or impurities from the aluminum liquid as the bubble rises.

The flow control of inert gas into liquid aluminum can be adjusted according to the volume of metal liquid to be treated. The speed of rotary rod and rotor can be adjusted to produce bubbles of appropriate size for the diffusion of inert gas.

Argon and nitrogen can be used as inert gases for degassing molten aluminum. The purity of inert gas must be above 99.99%.

Degassing System is the removal of hydrogen by injecting inert gas into molten aluminum.

Metal Degassing is also considered a very effective way to float impurities.

Two main theoretical models have been proposed to explain the principle of degassing.

The macro model assumes that the removal of each impurity is similar in nature.

In the microscopic model, according to this theory, dissolved hydrogen diffuses into the gas body of the injected liquid aluminum due to its high vapor pressure. In theory, an inclusion with a diameter of 10 microns comes into contact with a bubble, and it sticks to the bubble and rises to the surface of the liquid.

Degassing System for Romania Aluminium can eliminate hydrogen and other residues contained in the molten aluminum and its alloys that affect its quality and mechanical properties.

One of Romania’s largest vertically integrated aluminium producers, Alro, has notified Transelectrica, the country’s electricity transmission system operator, to curb proposed electricity consumption as the metal company should shut down some electrolysis units that produce aluminium.

Rising electricity prices have forced Romania’s largest industrial energy consumer to plan to cut its aluminium production by 60% in 2022.

According to Transelectrica, “Alro is allocated 917 megawatts of electricity that it can consume”. And according to one of Romania’s most relevant online publications for economic news and analysis, it shows that Alro’s consumption will be around 335 MWh in 2021.