Effective treatment of aluminum slag generated in the casting process

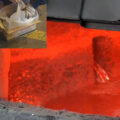

Aluminum slag is an inevitable part of the melting and casting process. Although relevant measures are taken, a certain proportion of metal aluminum will be taken out. It needs to be effectively treated instead of directly sold to other units. The simplest and economical method can be The aluminum slag is repeatedly milled and then screened using a mill to effectively recover part of the aluminum.

Reduce the slope of the slag slope of the mixing furnace, and fully extract the aluminum slag out of the furnace

The slope of the slag slope of the mixed furnace directly affects the amount of aluminum slag. If the slope is too large, most of the slag will not be extracted, resulting in a large amount of aluminum slag and aluminum deposits. When cleaning the furnace, the slag and aluminum deposits cannot be recovered in time. On the premise of ensuring the capacity of the mixing furnace, reduce the slag slope as much as possible.

Strictly control the quality of slagging to prevent liquid aluminum from being taken out

The existing slagging operation basically uses a large rake to pull the aluminum slag out of the door of the furnace. During this operation, in addition to requiring careful operation by personnel, do not take out the molten aluminum as much as possible. At the same time, the design of the large rake also needs to be exquisite. Several rows of small round holes are made on the surface of the rake, so that the liquid aluminum contained in the aluminum slag can flow into the furnace, otherwise the excessive liquid aluminum will be brought out and returned to the furnace, which will cause burning.

Reduce the amount of defective aluminum and bulk aluminum

In the production process, strictly follow the process requirements to ensure that one furnace is produced and one furnace is qualified. Especially in the production of general aluminum, as far as possible, the production of inferior aluminum such as flash, burrs, ripples, and weight inconsistencies should be avoided. Before the end, push the liquid aluminum in the launder into the mold as much as possible to form a qualified product to reduce the amount of bulk aluminum.

Effective Treatment of Aluminum Slag

Fluxes for aluminum and aluminum alloys are generally composed of chlorides and fluorides of alkali metals and alkaline earth metals, but the content of components varies greatly, and the effects are also different. In addition to using the flux produced by the flux factory, it is best to adjust the flux composition ratio according to the composition of the aluminum alloy to be smelted. At the same time, strictly control the refining process conditions, such as the amount of flux, contact time between the flux and the melt, contact area, stirring condition, temperature, etc. The use of refining agents can effectively reduce the aluminum in the slag and reduce the casting loss.