In addition to considering the actual production quality requirements for aluminum products, the selection of aluminum metal foam filter must also consider the aluminum flow rate of the flume during casting and rolling, the total amount of filtration, the cleanliness of the aluminum liquid itself, and the production cost. Choosing Foundry Ceramic Filters with too high specifications will increase costs and reduce production efficiency.

Foundry Ceramic Filters Requirements

The requirements for aluminum metal foam filter are:

- The size specifications must be accurate.

- Ensure the flatness of the ceramic filter plate.

- Have accurate porosity, so as to choose according to the filtration accuracy and flow rate, and have a certain air permeability.

- Have a certain sintering strength as a parameter to measure whether the slag is dropped.

- The surface hardness of the foundry ceramic filters should be high, and special coatings should be applied.

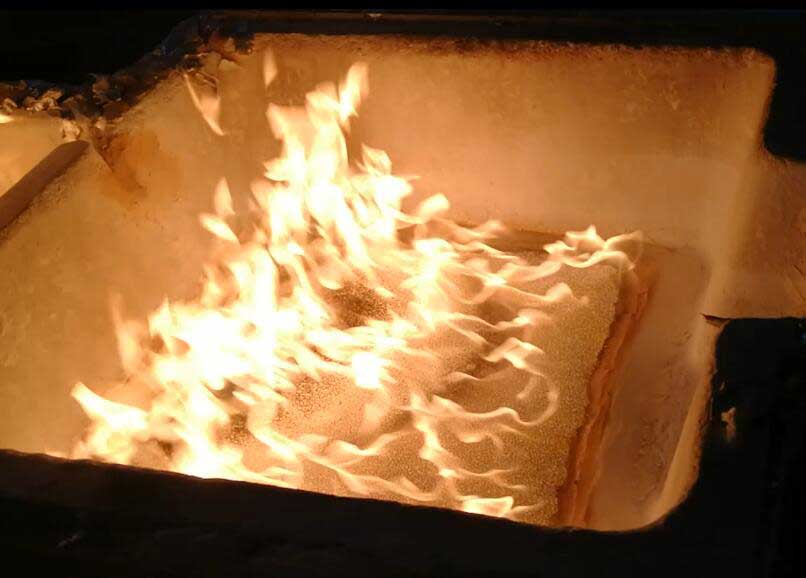

- The ceramic foam filter plate needs to be washed with heat-resistant aluminum liquid. Because the high-temperature aluminum liquid suddenly contacts the filter and makes the filter close to the temperature of the liquid when it is released. The metal foam filter should have a small linear expansion coefficient. The film is not allowed to be washed out and softened.

- The chemical stability of the filter is high, and it does not react with aluminum at high temperatures.

Ceramic Foam Filters For Casting

The principle of the installation position of the foundry ceramic filter should prevent the filtered aluminum melt from flowing into the crystallizer without turning over. For the horizontal flow channel, since the oxide film in the flow channel is continuous, the filter installation location need not be very far from the crystallizer near. Before installing the filter, lightly pat the filter to remove the residual ceramic debris and remove the debris in the flow slot, so as to avoid clogging the foundry ceramic filter. The combination between the installed filter and the flow slot must not leak.

When filtering with a ceramic foam filter plate, with the formation of surface deposition, the CFF filter in the filter box can intercept both large particles and small particles. When the adsorbed particles reach saturation, that is, when the number of particles adsorbed from the melt is equal to the number of particles taken away by the flowing melt, the slag removal capacity decreases. It needs to replace the new ceramic foam filter.

Ceramic Filter for Foundry: The Ultimate Solution for Casting Purity

In the modern metallurgical industry, casting quality is the primary determinant of profitability. Ceramic Filters for Foundry applications are engineered to solve the most critical challenge in metal casting: non-metallic inclusions.

Whether you are operating a low-pressure aluminum die casting plant or a high-temperature iron foundry, our advanced ceramic filtration systems provide the laminar flow and inclusion removal necessary to produce zero-defect castings.

Why Every Foundry Needs Advanced Ceramic Filtration

Using a high-quality ceramic filter is not just a cost; it is an investment in yield rate. Unfiltered molten metal contains slag, dross, and oxide films that lead to casting rejection and expensive rework.

Integrating our ceramic filters into your gating system delivers three immediate benefits:

-

Elimination of Inclusions: Effectively removes micron-sized impurities through deep-bed filtration.

-

Turbulence Reduction: Converts turbulent metal flow into a smooth, laminar flow, preventing air entrapment and mold erosion.

-

Increased Yield: Reduces the scrap rate by up to 50-80%, significantly lowering production costs.

Types of Ceramic Filters for Foundry Applications

We offer a comprehensive range of filters tailored to specific casting temperatures and alloy types. Choosing the right material is critical for safety and performance.

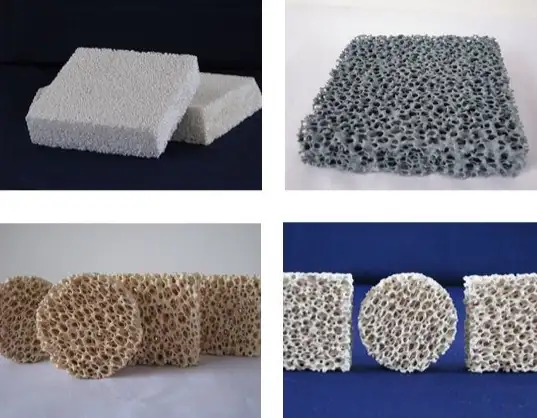

Different types of ceramic filters for foundry: Alumina, SiC, and Zirconia

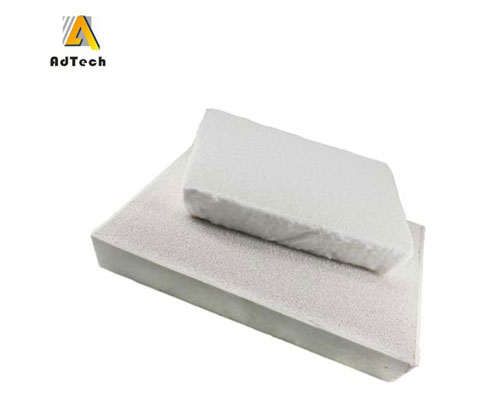

1. Alumina Ceramic Foam Filters (CFF)

-

Target Alloy: Aluminum and Aluminum Alloys.

-

Temperature Limit: Up to 1100°C.

-

Mechanism: Uses an internal 3D network structure to capture fine oxides in aluminum melts.

-

Best For: Aluminum billets, slab casting, and precision foundry parts.

2. Silicon Carbide (SiC) Ceramic Foam Filters

-

Target Alloy: Grey Iron, Ductile Iron, Copper, and Bronze.

-

Temperature Limit: Up to 1500°C.

-

Mechanism: High thermal shock resistance allows it to withstand the aggressive heat of molten iron while filtering out slag and sand inclusions.

-

Best For: Sand casting and iron foundry applications.

3. Zirconia Ceramic Foam Filters

-

Target Alloy: Carbon Steel, Stainless Steel, and Superalloys.

-

Temperature Limit: Up to 1700°C.

-

Mechanism: Extreme refractoriness ensures the filter remains solid during the pouring of heavy steel castings.

-

Best For: Large scale steel casting and aerospace components.

4. Extruded Ceramic Filters (Honeycomb)

-

Target Alloy: Grey Iron and Aluminum.

-

Structure: Straight-channel honeycomb design.

-

Advantage: High mechanical strength and cost-effectiveness for large volume flows where fine filtration (PPI) is less critical than flow rate.

Technical Specifications & Selection Guide

Engineers should select the correct Pore Size (PPI – Pores Per Inch) based on the casting requirements. A higher PPI means finer filtration but higher flow resistance.

| Filter Type | Color | Main Component | Max Temp (°C) | Common PPI | Application |

| Alumina CFF | White | Al₂O₃ | 1100°C | 10, 20, 30, 40, 50, 60 | Aluminum Foundry |

| SiC CFF | Grey/Black | SiC | 1500°C | 10, 20, 30 | Iron/Copper Foundry |

| Zirconia CFF | Yellow | ZrO₂ | 1700°C | 10, 20, 30 | Steel Foundry |

| Extruded | White/Brown | Cordierite/Mullite | 1450°C | 100-300 CPSI | General Casting |

Pro Tip: For most gravity casting aluminum applications, 30 PPI or 40 PPI is the industry standard balance between flow rate and filtration efficiency.

How It Works: The Filtration Mechanism

To rank as a top-tier foundry supplier, it is essential to understand that our filters work through three distinct physical mechanisms:

-

Screening (Sieving): Large particles of dross and slag that are physically larger than the filter pores are mechanically blocked at the filter face.

-

Filter Cake Filtration: As large particles accumulate on the surface, they form a “filter cake” that helps trap even finer particles, increasing efficiency over time.

-

Deep Bed Adsorption: This is the advantage of Foam Filters. Small inclusions that pass through the surface are trapped inside the tortuous path of the ceramic body due to surface tension and chemical affinity.

Installation and Placement in the Gating System

For maximum effectiveness, the ceramic filter should be placed as close to the casting cavity as possible.

-

Filter Cup / Pouring Basin: Ideal for direct pouring to prevent turbulence entering the sprue.

-

Runner System: The most common placement. Ensure the runner cross-section is expanded at the filter placement area to prevent flow restriction (choking).

-

Benefit: Proper placement ensures that the metal entering the mold cavity is calm and free of oxides.

Frequently Asked Questions (FAQ)

Q: How do I choose the right PPI for my foundry?

A: Lower PPI (10-20) offers high flow rates for large castings. Higher PPI (40-60) provides superior filtration for high-quality parts like aerospace or automotive components but requires higher metal head pressure.

Q: Can ceramic filters withstand thermal shock?

A: Yes. Our SiC and Alumina filters are engineered with low thermal expansion coefficients to resist cracking during the sudden temperature rise of pouring. However, for large filters, pre-heating is recommended.

Q: What is the shelf life of a ceramic filter?

A: When stored in a dry, ventilated environment, ceramic filters typically have a shelf life of 2-3 years. They must be kept dry to prevent moisture absorption, which can cause cracking during casting.