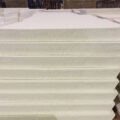

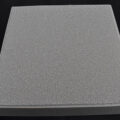

Molten Metal Filtration Australia is a new type of industrial ceramic product with low bulk density (0.25-0.65) g/cm3, high porosity (60-90%), and three-dimensional network framework.

Ceramic foam filter has the characteristics of high temperature resistance, chemical corrosion resistance, interpenetration, large specific surface area and so on. Ceramic foam filter is widely used in metal melt filtration, high temperature flue gas purification treatment, chemical filtration, carrier and photothermal conversion and other fields.

Especially in the field of aluminum melt filtration, some companies at home and abroad have developed from the purification of screen mesh and straight hole honeycomb tiles to the foam aluminum water filter in the current casting system.

Molten Metal Filtration Australia has significant effects in reducing castings rejection rate, improving mechanical properties of castings, extending service life of Metal cutting tools and reducing overall costs.

The liquid aluminum purification technology develops rapidly in China, and the production of high-quality castings increases gradually.

There are many manufacturers of melt purification equipment and testing equipment, such as Selle, Foseco, AdTech, etc.

The aerospace industry has a high demand for aluminum alloy castings.

The operation method of slag formation after rotary degassing of inert gas is adopted for liquid aluminum purification.

For higher requirements of liquid aluminum, after treatment by hexachloroethane can meet the product requirements.

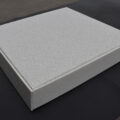

Ceramic foam filter is installed in the filter box. Alumina ceramic foam filters are resistant to molten metal being filtered and are resistant to thermal shock, erosion and corrosion, allowing molten metal to flow through.

The porous filter member is seated in the filter box liner with gasket material between the perimeter of the porous filter and the liner to tightly seat the porous filter in the filter box. The gasket material can be any known high temperature, low density compressible ceramic fiber material or other known gasket material. Typically, each component is removable for easy filter replacement.