Aluminum scrap usually contains high concentrations of various impurities. In the case of using aluminum scrap as a part of aluminum raw materials, it is necessary to remove inclusions from molten aluminum obtained by melting aluminum raw materials. Therefore, in addition to refining processes such as degassing molten aluminum using a flux, processes for removing impurities from molten aluminum, such as a killing method, an active gas method, and ceramic foam filtration of molten aluminum.

According to the killing method, the molten aluminum can stand undisturbed. Since the specific gravity of the inclusions differs from the specific gravity of molten aluminum, this static state causes the inclusions in the molten aluminum to float or settle to the bottom of the molten aluminum. Thus, it is possible to achieve separation of inclusions from molten aluminum. However, the separation efficiency is extremely low. This is due to the fact that the specific gravity of inclusions and molten aluminum is not very different, and the wettability is quite high. Therefore, even after a long time after the completion of the method, there is still a problem that a large amount of inclusions remain in the molten Al.

In the reactive gas method, inert gas is introduced into molten aluminum to form bubbles. The inclusions adhere to the bubbles and float together in the molten aluminum, thereby separating the inclusions from the molten aluminum. This method is especially useful for removing gases such as hydrogen. However, the rising air bubbles cause the surface of the molten aluminum to vibrate violently, thereby stirring the molten aluminum. This causes another problem in that the alumina film formed on the surface of the molten aluminum may again mix with the molten aluminum, resulting in an increase in the number of alumina inclusions.

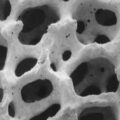

According to the method of filtration of molten aluminum, molten aluminum is passed through a refractory filter to remove inclusions therefrom. The larger particles of inclusions can be removed from the molten aluminum. However, it is difficult to remove small particles of inclusions of 100 µm or less, which make up the majority of the inclusions. In particular, it is difficult to remove small particles of inclusions with a size of about 10 to 25 microns, although such removal is unavoidable in order to obtain high quality aluminum alloys. To remove such small particles of inclusions, a traditional filter must have a finer mesh. However, if the screen openings are too small, when there are many inclusions in the molten aluminum, the filter will clog during short-term operation, leading to the practical problem of shortening the filter life.

AdTech has developed a new type of foamed ceramic filter that improves the efficiency of removing particularly small inclusions around 10-25 microns in size.