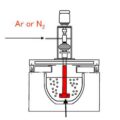

As the demand for premium aluminum products increases, especially in the aerospace industry, the need to reduce the occurrence of inclusions in molded products also increases. A popular remove hydrogen method is to introduce nitrogen gas bubbled through liquid aluminum. The hydrogen is attracted to the nitrogen bubbles, then transported through the aluminum and released to the surface. Argon is also very efficient, but due to the high costs associated with this gas, nitrogen is preferred.

Adtech Remove Hydrogen Method – Online Degassing Unit is mainly used for the removal of hydrogen (H) and slag from molten aluminum.

It takes the principle of gas flotation. The degassing rotor takes an inert gas or a mixture of chlorine and inert gas in molten aluminum and crushes the gas into tiny scattered bubbles, the bubbles rise to the surface of the molten aluminum and complete the procedures given below by the same time:

H is absorbed in bubbles and is eliminated.

Chloride is removed (formed by chemical action with alkali metal and chlorine gas).

Remove the slag.

Online Degassing Unit Instruction:

Switch off the heater after the degassing box has finished heating. Guide the inert gas into the rotor and release the molten aluminum in the can when the heater temperature is closed to the temperature of the molten aluminum.

Check the seal between the inlet/outlet and the washing machine.

Check the cone located in the thermal protection draining in the bottom.

Check the temperature of the molten aluminum (min 720 ° C). Measure the height of molten aluminum away from the bottom of the washing machine at 3 cm to observe the molten aluminum entering the box.

The operator must wear protective clothing to close the cover. Surface slag can be skimmed off through the scouring outlet as molten aluminum flows into the can.

Start production when the temperature reaches 780 ° C. Close the scouring outlet to conserve heating.

Molten aluminum can be retained in the can with a set temperature during the heat preservation phase but without handling molten aluminum.

Guide the inert gases into the rotor to avoid blockage of the air outlet by molten aluminum.

Turn on the heater as soon as the molten aluminum flows into the can and adjust the heat preservation settings.

Start the heating system, control the temperature of molten aluminum, monitor the gas flow, the rotor speed is changed from the heat preservation stage to the processing stage. At the same time, the flow rate of inert gas in the rotor increases and the gas flow rate is changed from the preservation stage to the processing stage.

The operator regulates the heating temperature of molten aluminum, maintains a stable degassing working condition.