At present, there are many kinds of detection methods for inclusions in molten aluminum at home and abroad, mainly divided into offline detection and online detection. The main methods of offline detection include: metallographic method, filtration method, chemical analysis method, electron beam melting method, centrifugal heating method, ultrasonic method, etc. The online detection methods for inclusions mainly include: LiMCA method, LiMCAlI method, etc. At present, there are many researches on offline detection methods in China, but these methods are performed offline, that is, samples must be taken at the production position, and then the samples are processed and tested in the laboratory, and the results are returned to the production, which is difficult to use on site Online detection cannot accurately reflect the true situation of inclusions in molten aluminum. There are many studies on online detection methods abroad, but its products are more expensive and costly.

The PoDFA (Porous Disc Filtration Analysis) system of Al-Canada is also a quality control tool used to determine the cleanliness of molten aluminum. It is the only quality control tool that can perform both qualitative analysis of inclusion properties and quantitative analysis of inclusion concentration. The manufacturer can formally determine whether the molten aluminum can be used in the production of products with strict requirements for inclusions based on the PODFA measurement results.

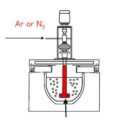

Qualiflash is a filtration technology that evaluates the cleanliness of molten aluminum. When molten aluminum enters a temperature-controlled hood with a filter at the bottom, the oxide will block the molded ceramic filter. The filtered metal is retained in an ingot mold with 10 graduations. Determine the cleanliness of the molten aluminum according to the amount of aluminum in the ingot mold when the molten aluminum stops flowing. Qualiflash is a portable instrument that can be used for pre-furnace analysis, and a test only takes 20 seconds.

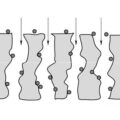

A typical equipment for measuring inclusion content by filtration is the prefil footprinter developed by Canada Bomem Inc. The test result is the relationship curve between the quality of the filtered metal and the time. Compare the slope of the curve with the standard molten aluminum inclusion level for a given alloy, production process or stage to determine the inclusion content. The greater the slope, the less the inclusion content.

The fracture inspection method estimates the number of inclusions by observing the percussion fracture, which can realize online detection, but the results are scattered and the accuracy is not high. It can only be used as a qualitative reference. Some scholars believe that the fracture inspection method is mainly suitable for the pre-furnace inspection of some aluminum alloys and zinc alloys, and is generally not suitable for pure aluminum and alloys with very small amounts of alloying elements.