Thermal Efficient Launder Systems is used for the transfer and transportation of molten aluminum between aluminum melting furnaces and from furnaces to various casting equipment.

These launders all adopt a grooved structure with a steel shell, and the launders are assembled in sections by prefabricated refractory materials.

Thermal Efficient Launder Systems is provided with an electric heater between the inner tank and the steel shell, and the launder is provided with a sealing groove at both ends of the inner tank.

The inner bladder of the launder and the steel shell are connected by a compression flange and sealed with refractory mud.

The launder device also includes an electrical control system connected to the electric heater, and the electrical control system can realize independent control of each heater, thereby achieving constant control of the temperature of the launder at a temperature close to that of the casting melt.

The problem of temperature drop in the casting launder is eliminated, the realization of the aluminum ingot casting process is ensured, and the melting temperature of the casting holding furnace is reduced, the energy consumption of the holding furnace is reduced, and the service life of the launder is also prolonged.

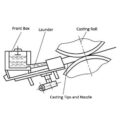

Aluminium rod ingot casting device for conveying launder liquid level stabilization cable, including conveying launder, holding furnace, molten aluminum flow control valve, liquid level detection mechanism, and molten aluminum flow control valve to control the opening of the furnace mouth of the holding furnace size.

The liquid level detection mechanism is arranged above the liquid level monitoring section close to the aluminum section, and the liquid level detection mechanism includes an infrared ranging sensor, a processor, and a floating plate.

The liquid level detection mechanism is set close to the furnace nozzle, so as to avoid the overflow or underflow of the cooling section aluminum liquid caused by the detection delay caused by the installation of the liquid level detection mechanism far away from the furnace nozzle, which will cause partial aluminum rods to be cast subsequently thinner.

In the rolling process, the problem of rod breakage occurs. The aluminum liquid flow control valve is used to control the opening of the furnace nozzle. Compared with the integral rotation method of the tilting holding furnace, the response is rapid, and the cooling section caused by the detection delay is further avoided. Overflow or underflow of molten aluminum.