Wall cleaning fluxes help keep crucible and furnace walls above and below the melt line free of oxide build-up. This reduces both alloy wastage and another source of unwanted inclusions.

Wall cleaning fluxes soften oxides built upon the furnace walls. Wall cleaning fluxes contain double fluorides (Na2SiF6, Na2AlF6) and an oxidizing agent. The oxidizing agent reacts with aluminum generating heat, which promotes penetration of fluorides into the built-up oxides softening them. The softened oxides are easily scrapped from the wall by the furnace operator.

Cleaning fluxes remove oxides suspended in the aluminum melt. Similar to the Drossing fluxes, cleaning flux is composed of a mixture of chlorides, fluorides, and an oxidizing agent. Cleaning fluxes generate less heat therefore their aluminum separation effect is lower. However, they possess a better ability to absorb oxides inclusions from the melt.

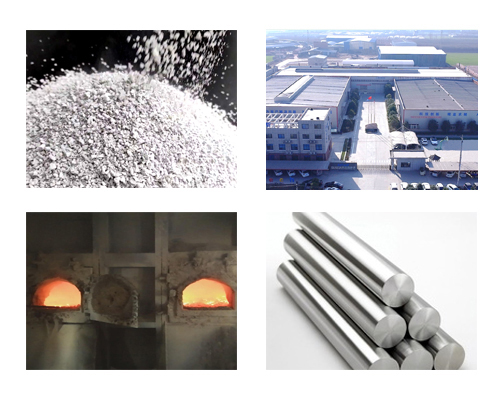

The common practice of flux introduction is manual application. Most of the fluxes are applied to the melt surface and stirred into the melt. Some of the fluxes (degassing, grain refining) are plunged to the bottom by a clean preheated perforated bell.

Fluxes may also be introduced into the melt by injection in form of a powder in an inert gas (Argon or Nitrogen) stream. The simplest flux injection technique is a lance immersed into the melt. The most effective flux introduction method is injection by rotary degasser.

Pass nitrogen (pressure is 1.2~1.8kg/cm2) and then open the switch under the refining tank. The gas used is 99.99% high purity nitrogen. The pressure of nitrogen during refining is better under the condition that it can blow out the powder. The amount of refining agent is about 0.15~0.20%.

The refining temperature is controlled at about 730-750 degrees Celsius, and the slag can be scraped after standing for 20 minutes after refining. Try to avoid stirring the aluminum liquid when scraping the slag, so as not to entrap the slag into the aluminum liquid, and then use the covering agent to melt the surface to prevent melting The body re-oxidizes and absorbs.