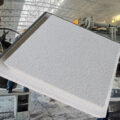

Casting Filter Australia is characterized by corrosion resistance, high temperature resistance, high mechanical strength, no dissolution of harmful substances and no secondary pollution. Under the action of fluid pressure, the microhole is not deformed, easy to clean regeneration, long service life. Widely used in environmental protection of metallurgical enterprises. Casting Filter Australia adopts a new process […]

The use of alumina foam ceramic filters for foundry can purify molten aluminum, it has brought huge benefits to the strip foil and its products. For manufacturers of aluminum alloy profiles, there are several advantages: Improve extrusion productivity: When using foam ceramic filters to purify alloy extrusion materials, we have inspected a certain mold and […]

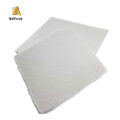

The initial foam ceramic filters manufacturing is formed by coating the reticulated polyurethane precursor with a ceramic slurry. The reticulated open-cell foam, preferably polyurethane foam, is impregnated with the ceramic slurry, wherein the entire structure of the reticulated open-cell foam is preferably covered by the slurry. The pore size of the foam is preferably between […]

The purification of metal liquid plays an important role in improving the mechanical properties of castings. At present, the filtering device used to purify the metal liquid is mainly ceramic foam filters for aluminium casting, which can effectively intercept harmful impurities in the metal liquid and convert the metal liquid from turbulent flow to laminar […]

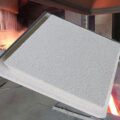

The inclusions are removed in the final processing step before solidifying the molten aluminum into an ingot or billet by filtration. The industry has been completed in the industry for many years by using a variety of technologies, including bed filtration and ceramic foam filter molten aluminum filtration. The production of aluminum ingots and billets […]

When these inclusions appear in the final cast product after the molten aluminum is solidified, they cause the final aluminum product to be less ductile or to have poor finishing characteristics. Therefore, it is important to remove entrained solids from the molten aluminum before it is cast into a solid body. In general, the ceramic […]