How to select molten metal filters? You need to understand which filter material is suitable for your metal casting and the characteristics of the filter. Foam ceramic is an ideal form of structure. The pore size and number of pores of this structure determine the resistance of the metal liquid through the filter. When non-metallic […]

Tag Archives: Ceramic Foam Filter Manufacturer Process

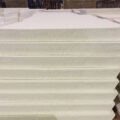

Alumina ceramic foam filters are specially developed by AdTech for molten Alu filtration. The molten aluminum flows through the tortuous and porous three-dimensional foam structure, and the tiny impurities are trapped, adsorbed, deposited, and firmly adhered to the pore walls, filtering out the micron-level impurities in the molten aluminum, and solving the aluminum alloy’s sensitivity […]

The alumina ceramic foam filter for casting can capture the inclusions according to a certain mechanism, thereby purifying the metal. In 1978, the United States developed a new filter-ceramic foam filter, which provides a high-efficiency filter for the production of aluminum castings, and is widely used in the production of semi-continuous ingots and molded castings. […]

Foundry molten metal filtration requires good chemical stability and excellent filter function, especially for the collection and absorption of 1~10um small impurities and filter residue. The ceramic foam filter has a three-dimensional structure, it can improve the quality of castings on a large scale by changing the molten metal from turbulent flow to laminar flow, […]

In order to obtain the best mold filling rate, it is important to calculate the appropriate ceramic foam filters size for each specific casting application. The filter must be large enough so that it will not obstruct or block the flow of molten metal or be blocked by residual inclusions before casting is complete. In […]

The purification of molten metal plays an important role in improving the mechanical properties of castings. At present, the filtering device used to purify molten metal is mainly ceramic foam filter used for aluminium castings, which can effectively intercept harmful impurities in molten metal, convert molten metal from turbulent flow to laminar flow, and completely […]

Ceramic filters for aluminum foundry are commonly used to filter various molten aluminum. Ceramic filters for aluminum foundry formed by impregnating organic foam with an aqueous slurry, the slurry composition containing 20%-50% silicon carbide, 20-50% alumina, 1.5-5.0% aluminosilicate fibers, And it has been fired at a temperature of at least 1150°C so that the filter […]

Filtering of Molten Aluminum is a method of removing impurities by letting the aluminum alloy melt pass through a filter made of neutral or active materials, so as to separate solid inclusions suspended in the melt. According to the filtering properties, it can be divided into two categories. The filtering method of molten aluminum can […]

In the late 1970s, the United States made a sponge-like ceramic foam filter (CFF) made of alumina and chromium oxide. CFF filter for molten aluminum not only has good purification technology, but also is easy to use. The initial pressure difference through the melt is only 100-150mm, and once it passes, it only needs to […]

Porous ceramic filters filtration efficiency mainly has filtration accuracy, which refers to the particle size of the smallest solid impurity particles in the fluid medium. For ceramic filters, the filtration accuracy can reach 0.1Lm. The main factor that affects the porous ceramic filters filtration efficiency is the maximum pore diameter of porous ceramic filter elements. […]

- 1

- 2

Contact Us

TEL: +86 371-87095601

E-mail: sales@alalloycasting.com

About Us

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

Address

NO.39 GARDEN ROAD, JINSHUI DISTRICT

ZHENGZHOU, HENAN, CHINA

TEL: +86 371-87095601

E-mail: sales@alalloycasting.com